Case Study - O&G Drilling Tubular Repair

Streamline your entire process from Quoting through Production Schedule Management!

Background

The company in this case study repairs drilling tubulars as a service in the Oil & Gas industry. Drilling tubulars are used many times over their life to drill numerous wells.

The threaded ends and sealing faces can become damaged, which is found during periodic inspection. Drillpipe comes in different diameters, lenghths, threadtypes, steel grades, yield strenghts - among other features

The cost to repair varies significantly for various of these attributes. Because of this complexity, the Quoting process is very different from Stock Keeping Unit (SKU) quoting.

Determining the cost is not a simple matter of choosing a part number as you would for a SKU product business.

This company has not yet explored nor invested in the setup of and ERP software. Like many small businesses, it is running the business using Microsoft Office – Excel and Word. Excel is used for quoting, orders, managing production orders, and other data. The company is using QuickBooks to manage the financials, material purchases, suppliers, customers.

The company in this case study repairs drilling tubulars as a service in the Oil & Gas industry. Drilling tubulars are used many times over their life to drill numerous wells.

The threaded ends and sealing faces can become damaged, which is found during periodic inspection. Drillpipe comes in different diameters, lenghths, threadtypes, steel grades, yield strenghts - among other features

The cost to repair varies significantly for various of these attributes. Because of this complexity, the Quoting process is very different from Stock Keeping Unit (SKU) quoting.

Determining the cost is not a simple matter of choosing a part number as you would for a SKU product business.

This company has not yet explored nor invested in the setup of and ERP software. Like many small businesses, it is running the business using Microsoft Office – Excel and Word. Excel is used for quoting, orders, managing production orders, and other data. The company is using QuickBooks to manage the financials, material purchases, suppliers, customers.

Problem

The company has recognized that there is a significant opportunity to improve profitablity through more precise quoting and automatic calculation of production schedule

One solution explored was an ERP software. This is a big investment and change in processes for employees.

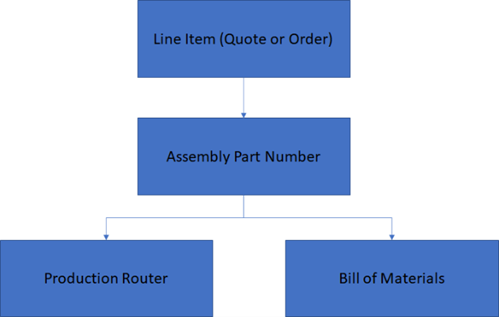

ERP software is designed to have an assembly (top level) part number for every line item (quote or order).

Below this assembly part number is a unique production router and bill of materials.

Using an ERP for a configured product to create a quote with 5 line items would require creation of: 5 assembly part numbers, 5 production routers and 5 bills of material (BOM). This is made somewhat easier by duplicating and then editing an existing router and BOM. The router is still a challenge however, because the process time for each of the production steps would need to be estimated and updated.-

The company has recognized that there is a significant opportunity to improve profitablity through more precise quoting and automatic calculation of production schedule

One solution explored was an ERP software. This is a big investment and change in processes for employees.

ERP software is designed to have an assembly (top level) part number for every line item (quote or order).

Below this assembly part number is a unique production router and bill of materials.

Using an ERP for a configured product to create a quote with 5 line items would require creation of: 5 assembly part numbers, 5 production routers and 5 bills of material (BOM). This is made somewhat easier by duplicating and then editing an existing router and BOM. The router is still a challenge however, because the process time for each of the production steps would need to be estimated and updated.-

Process Steps

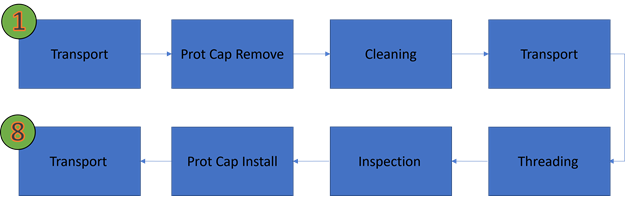

In this case study, the process steps are typically:

BOM

Because this business is a service and not manufacturing, a Bill of Materials is NOT required to determine the cost

Router

The key challenge and opportunity was with the router (production flow). While the steps would remain the same across all combinatations of Attributes, the time per step would vary greatly as a function of the Attributes- Transport

- Protective Cap Removal

- Cleaning

- Transport

- Threading

- Inspection

- Protective Cap Installation

- Transport

Clearly manual router creation is not practical.

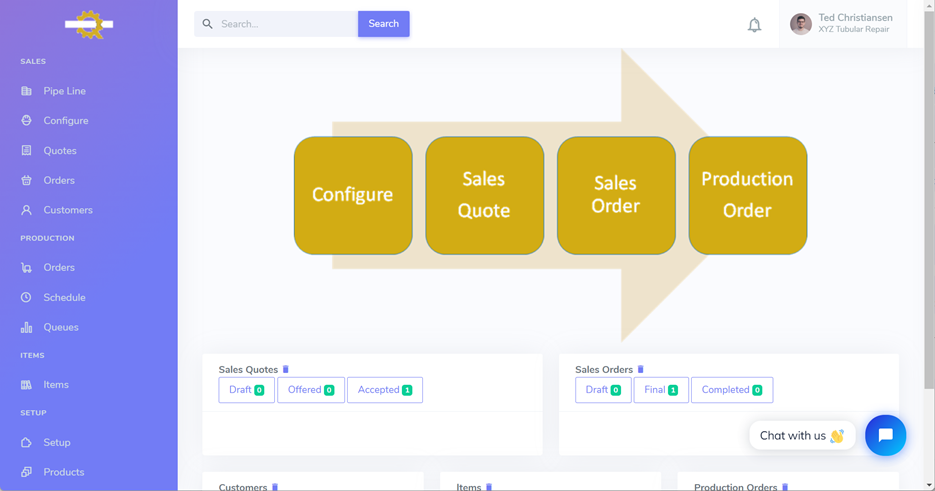

Solution

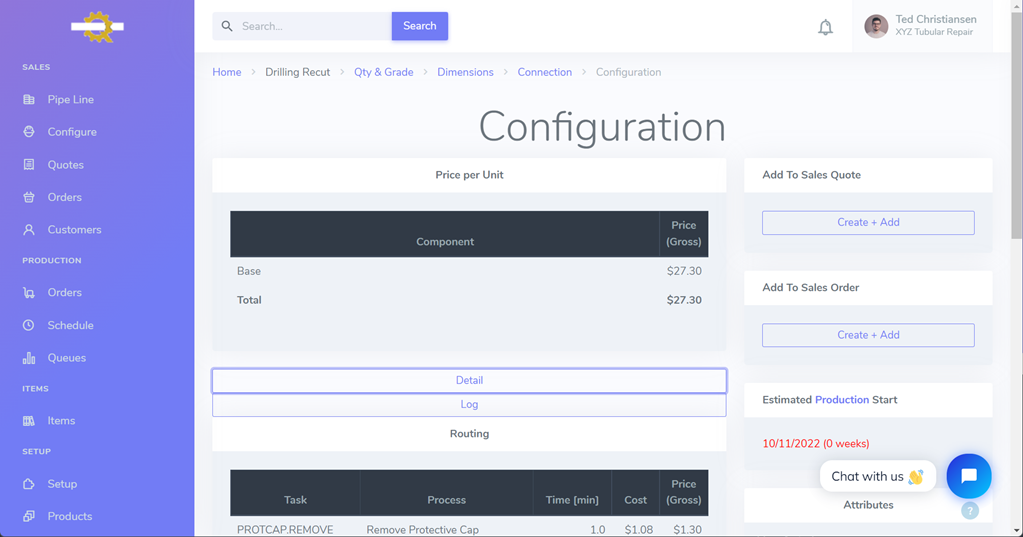

Velosity solves this problem uniquely. Velosity does not require the creation of: 1) assembly part numbers, 2) routers, 3) bill(s) of material. Instead, Velosity generates the router and BOM dynamically based on the product features (attributes) selected. To simplify this example, the MACHINING step is left out. MACHINING would require definition of machining types: 1) volume removal for facing, 2) volume removal from boring of various diameters, etc.

- Attributes (Product Specific)

- Items

- Tasks (Process Steps)

- Rules (Product Specific)

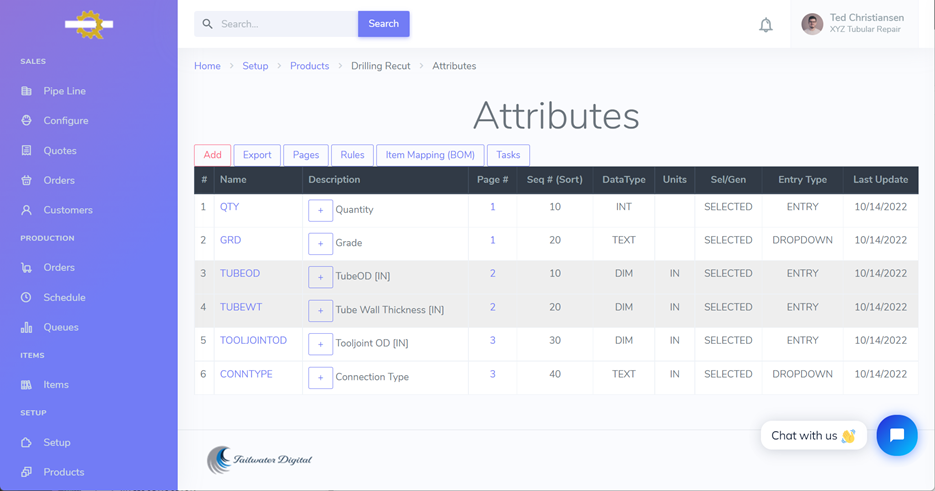

1) Attributes

The attributes that the user would select are shown here. These are setup in Velosity.

The attributes that the user would select are shown here. These are setup in Velosity.

Shown below are the Attributes as setup in Velosity

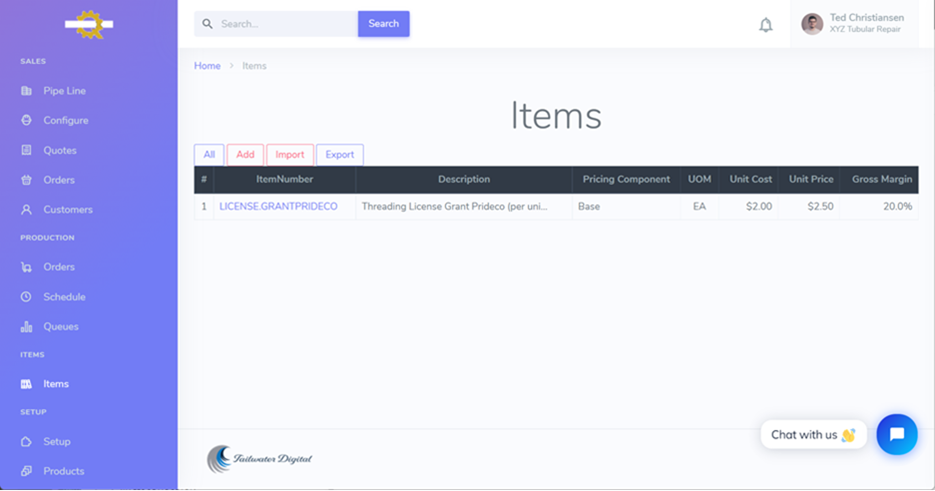

2) Items

The items that are added by the Rules or Item Mapping are shown here.

The items that are added by the Rules or Item Mapping are shown here.

Shown below are Items as setup in Velosity

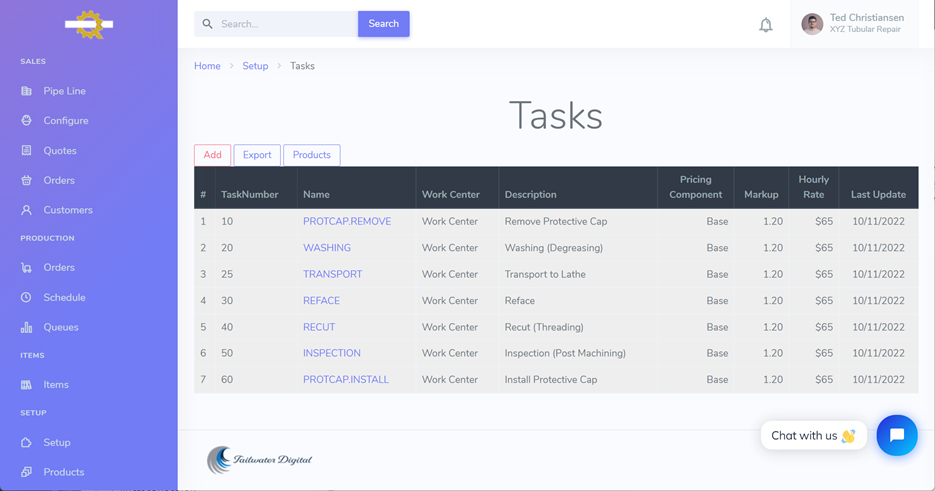

3) Tasks

The process steps (tasks) for this company are:- TRANSPORT

- PROTCAPREM

- CLEANING

- TRANSPORT

- THREADING

- INSPECTION

- PROTCAPINST

- TRANSPORT

Shown below are the Tasks as setup in Velosity

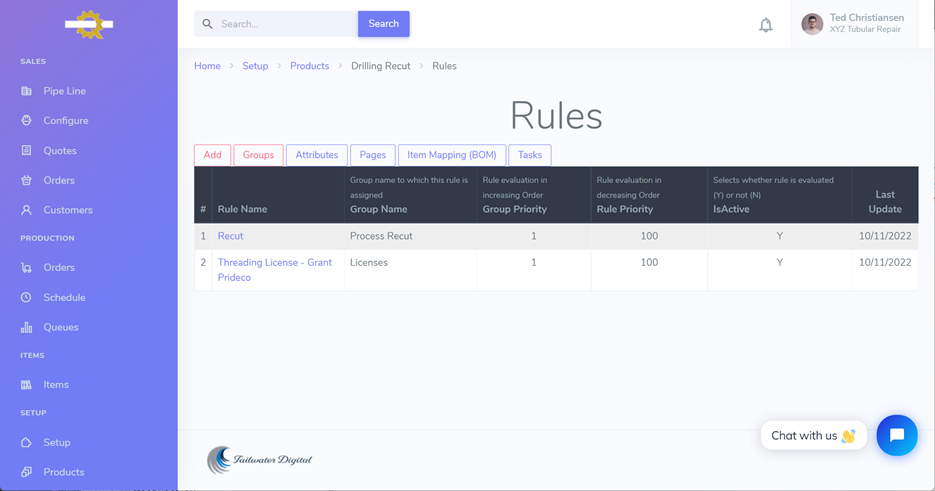

4) Rules

The rules that are evaluated to generate the router and BOM are shown here.

The rules that are evaluated to generate the router and BOM are shown here.

Shown below are Rules as setup in Velosity

Results

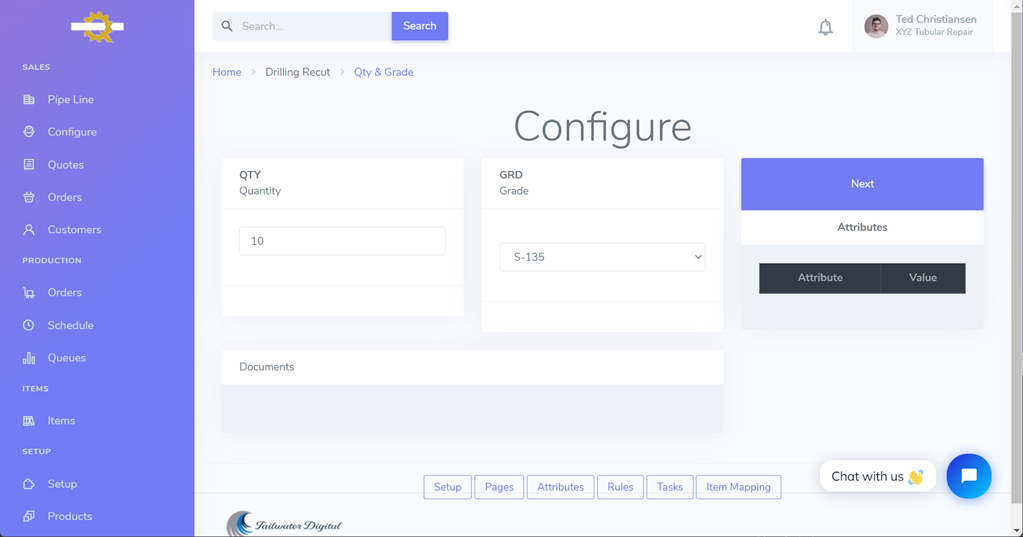

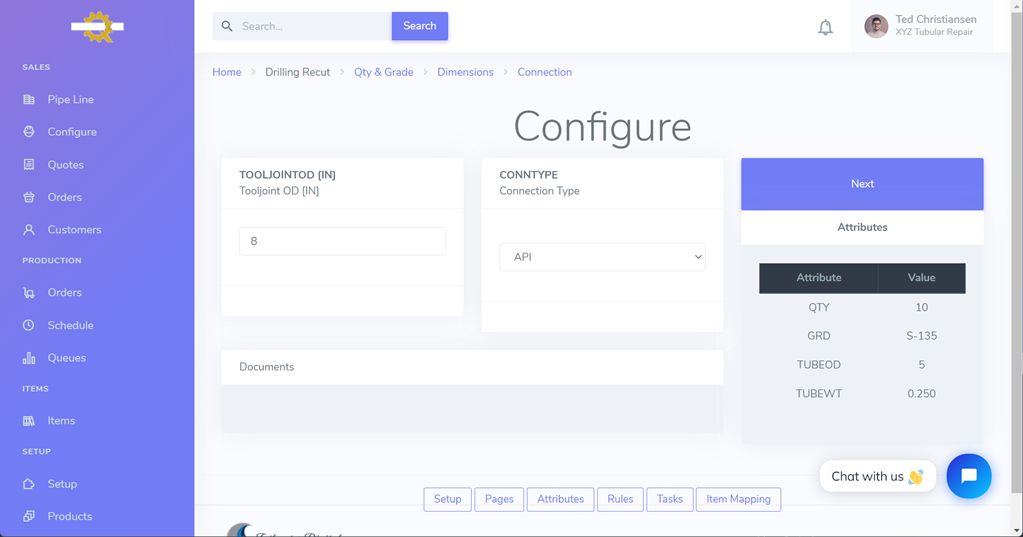

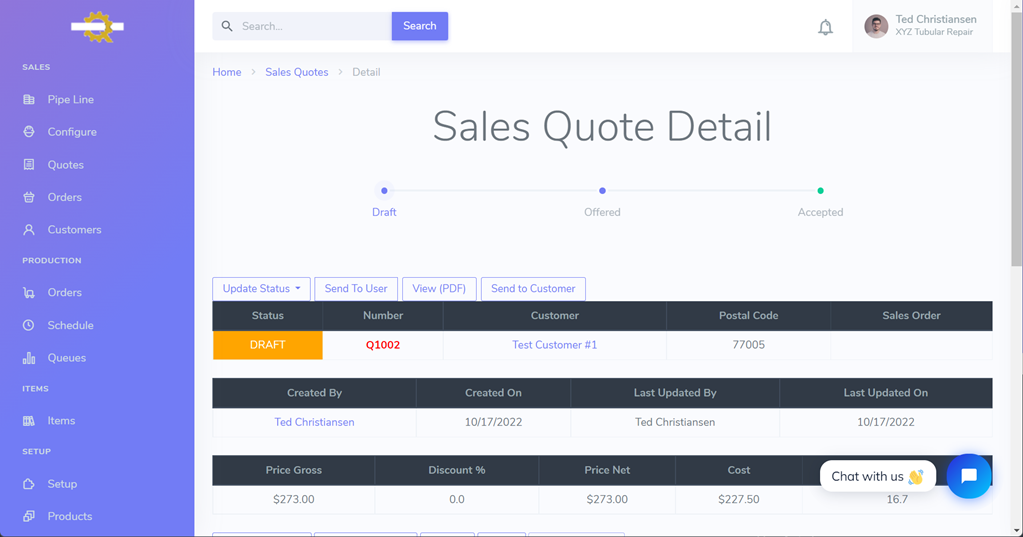

With this setup, the customer is able to generate quotes and orders within a few minutes (without creating any routers or BOM!), like this: