Case Study - OCTG Distributor

Streamline your entire process from Quoting through Production Schedule Management!

Background

The company in this case study distributes Oil Country Tubular Goods (OCTG) - specifically casing & tubing - in the Oil & Gas industry. Casing and tubing are used to complete (casing) and operate (tubing) oil and gas wells.

The well survey (3D), length, and completion design determine what diameter(s), yield strength, and threaded connection performance properties are required.

The combination of these features makes the Quoting process very different from Stock Keeping Unit (SKU) quoting. Determining the cost is not a simple matter of choosing a part number as you would for a SKU product business.

This company has an ERP, but because of the product complexity does not quote from it. Further, inventory is not managed in the ERP either.

The company in this case study distributes Oil Country Tubular Goods (OCTG) - specifically casing & tubing - in the Oil & Gas industry. Casing and tubing are used to complete (casing) and operate (tubing) oil and gas wells.

The well survey (3D), length, and completion design determine what diameter(s), yield strength, and threaded connection performance properties are required.

The combination of these features makes the Quoting process very different from Stock Keeping Unit (SKU) quoting. Determining the cost is not a simple matter of choosing a part number as you would for a SKU product business.

This company has an ERP, but because of the product complexity does not quote from it. Further, inventory is not managed in the ERP either.

Problem

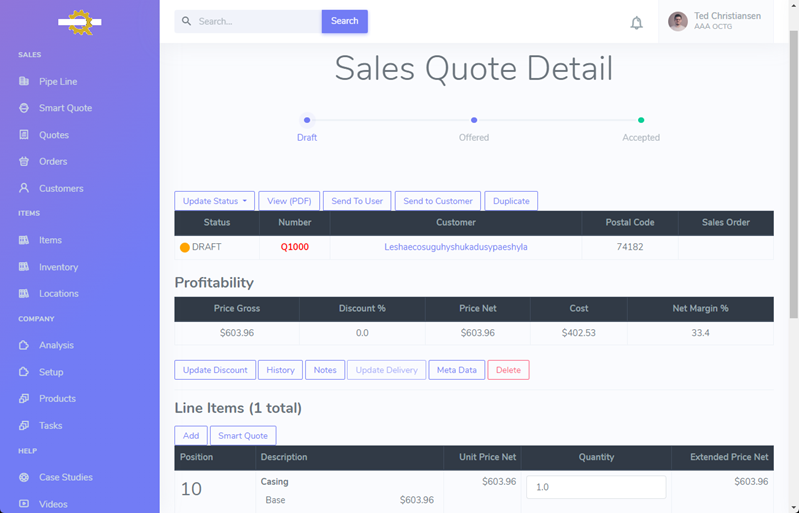

The company has recognized that there is a significant opportunity to reduce SG&A expense (thus improving profitablity) through quoting and automatic calculation of production schedule with lower expense.BOM

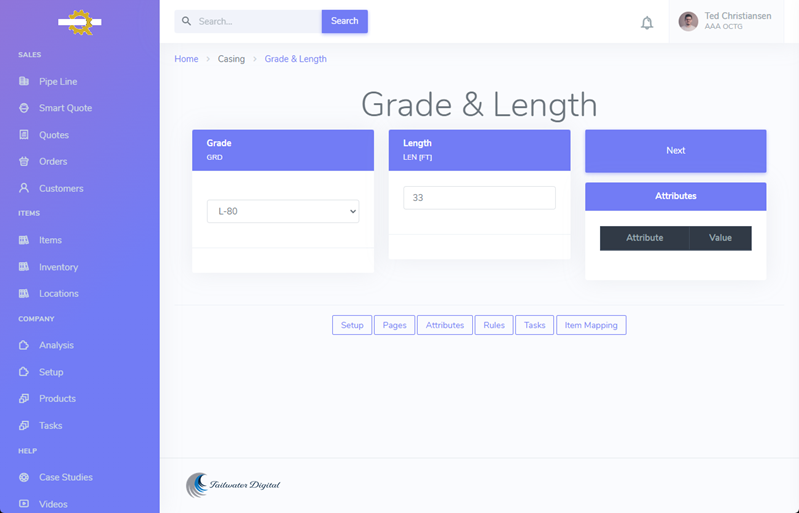

Because the process (router) is largely the same, the Bill of Materials is the primary driver to determine the cost. The material cost is a function of all of the product features (5-10):

- GRD - Grade

- CON - Connection (3-10 values)

- OD - Outer Diameter (10 values per CON)

- WT - Wall Thickness (5-10 valus per OD)

- LEN - Length (3 values)

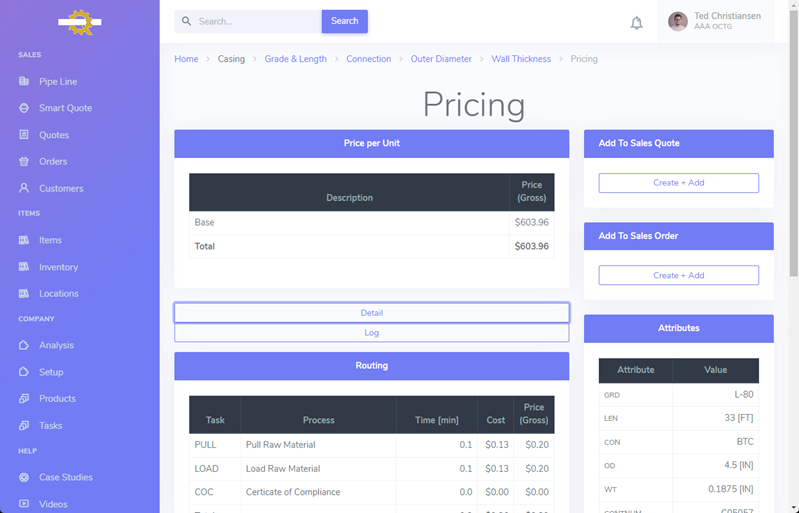

Router

While the steps would remain the same across all combinatations of Attributes, the time per step will vary somewhat- Pull

- Load

- Documentation

Solution

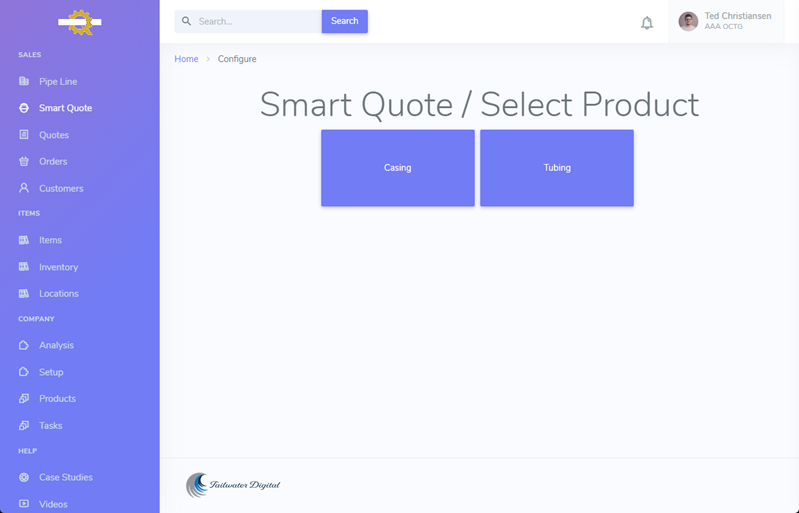

Velosity solves this problem uniquely. Velosity does not require the creation of: 1) assembly part numbers, 2) routers, 3) bill(s) of material. Instead, Velosity generates the router and BOM dynamically based on the product features (attributes) selected.

- Attributes (Product Specific)

- Items

- Tasks (Process Steps)

- Rules (Product Specific)

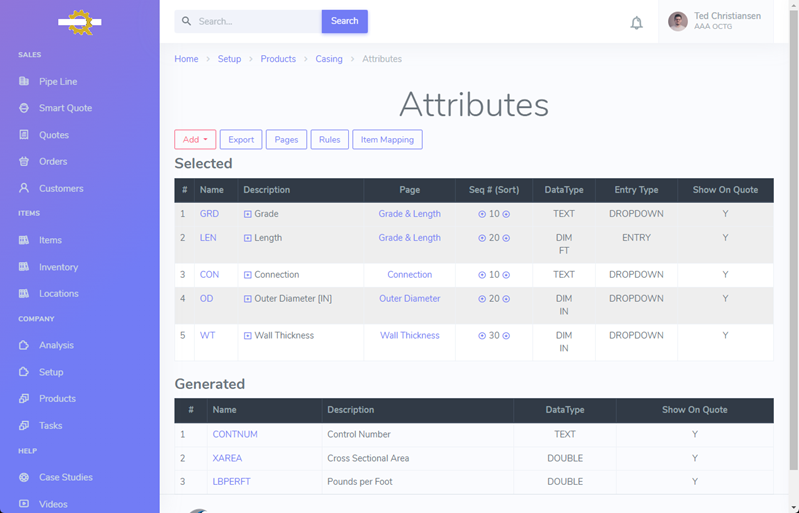

1) Attributes (Casing)

Shown below are the Attributes as setup in Velosity

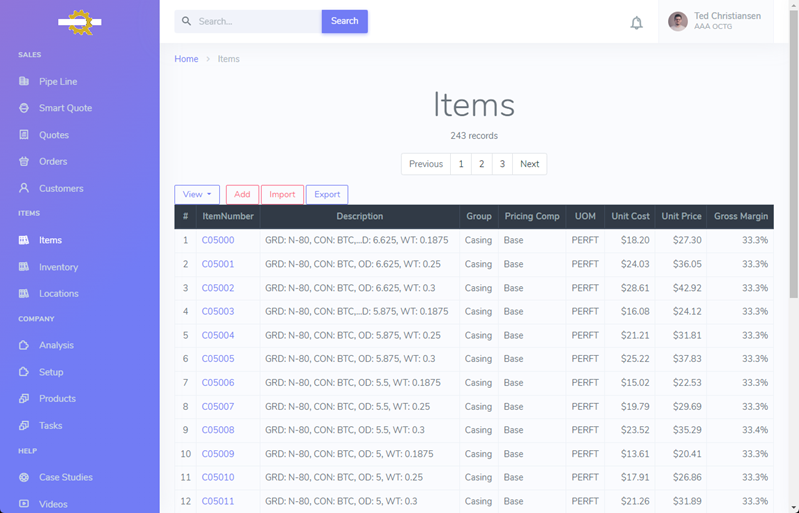

2) Items

Shown below are Items as setup in Velosity

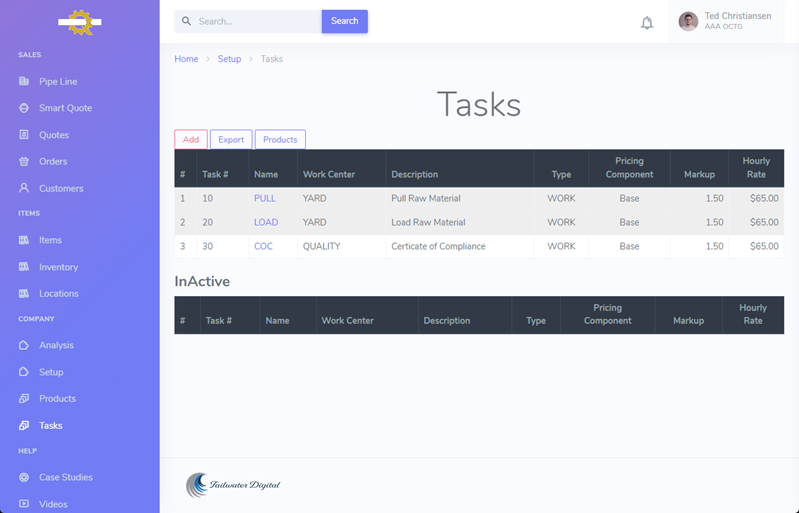

3) Tasks

The process steps (tasks) for this company are:- PULL

- LOAD

- QC_COC

Shown below are the Tasks as setup in Velosity

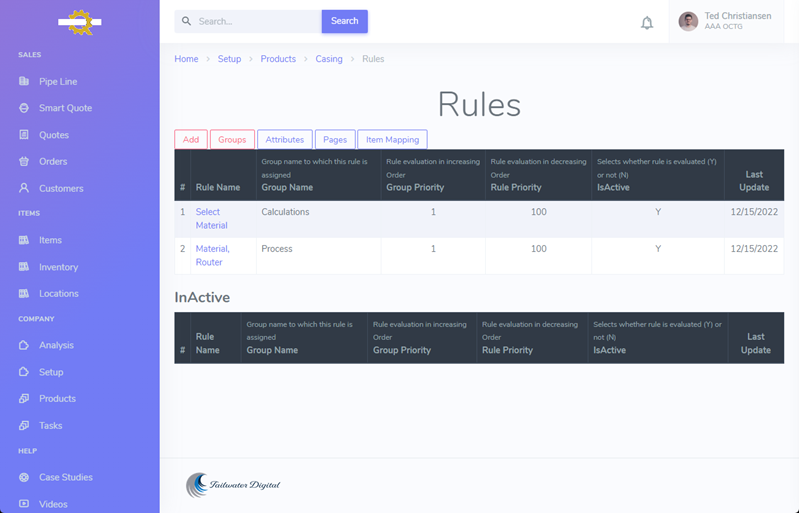

4) Rules

Shown below are Rules as setup in Velosity

Results

With this setup, the customer is able to generate quotes and orders within a few minutes (without creating any routers or BOM!), like this: