Case Study - O&G Meter Run

Streamline your entire process from Quoting through Production Schedule Management!

Background

The company in this case study manufactures meter runs - a skid mounted orifice plate flow meter with sensors and PLC controls - for liquid (oil) custody transfer. Customers are operators (oil companies).

The product measures the flow of oil that is injected into a pipeline gathering station so that the oil company can get paid.

Problem

The product has many customer selectable options, making quoting very cumbersome and time consuming - resulting in poor customer responsiveness and in some cases lost orders. To determine the cost and price requires a router and BOM for each unique combination of these choices - whether done in Excel or ERP software.

The total number of combinations of product features is: 2,721,600. This means 2.7 Million unique routers and BOMs are required. Clearly creating these routers and BOMs would not be done "upfront." Rather, it has been as needed.

- 4 - Fitting Brand

- 7 - Line Size: 2, 3, 4, 6, 8, 10, 12

- 3 - Flow Conditioner: None, A, B

- 3 - Outer End Type: Threaded, ANSI 150, ANSI 600

- 2 - Piping Class: SCH40, SCH80

- 3 - Fitting Head Position: 0, 90 Right, 90 Left

- 3 - Outer Isolation Valves: None, Ball, Ball + Check

- 4 - Blowdown Valves: None, 1/2, 3/4, 1 Inch

- 5 - Color: Tan, Battleship Grey, Pearl Grey, Enviro-green, Shale Green

- 3 - XMV Package: None, Pressure Range 1, Presssure Range 2

- 2 - Skid: No, Yes

- 3 - Thread-O-Let Accessories: None, TestWell + ThermoWell + Sample Probe

- 2,721,600 - Total combinations of all options (4 * 7 * 3 * 3 *2 * 3 * 3 * 4 * 5 * 3 * 2 * 3)

The router typically has 12 steps - meaning 12 production task times would need to be estimated for the specific combination of product features selected. The BOM typically has about 50 parts/subassemblies - meaning each of item in the BOM would need to be manually added as required by the specific set of product features selected. It should be clear that all of this is a lot of work. Even worse, with a low strike rate (quotes won/offered), the effort for lost quotes is wasted. In this company, one person's full time job was creating quotes in the ERP system.

The company has recognized that there is a significant opportunity to reduce SG&A expense (thus improving profitablity) with SmartQuote and automatic calculation of the production schedule.

BOM

- Fitting + Fasteners

- Tubing

- Flow Conditioner + Fasteners

- XMV (PLC Computer) + Fasteners

- Sensors

- Skid + Fasteners

Router

- ENG - Engineering

- WHSE - Warehouse

- QCINT - Quality Control - Internal

- PREP - Welding Prep

- WELD - Welding

- NDT - Non-Destructive Testing (X-Ray/Ultrasonic)

- GRND - Grinding of the welds

- HYDROPREP - Prep for Hydrostatic (water) test

- HYDRO - Hydrostatic pressure test

- ASSY - Assembly

- PAINT - Painting

- QCF - Quality Control Final

Solution (4 Weeks Onboarding)

Velosity solves this problem uniquely. Velosity does not require the creation of: 1) assembly part numbers, 2) routers, 3) bill(s) of material. Velosity generates the router and BOM dynamically based on the product features (attributes) selected.The onboarding required about 4 weeks. Setting up the Attributes, Tasks and Rules was done within Velosity. The Items and Item Mapping were imported via Excel (csv).

- Attributes (Product Specific)

- Items

- Tasks (Process Steps)

- Rules (Product Specific)

- Item Mapping (Product Specific)

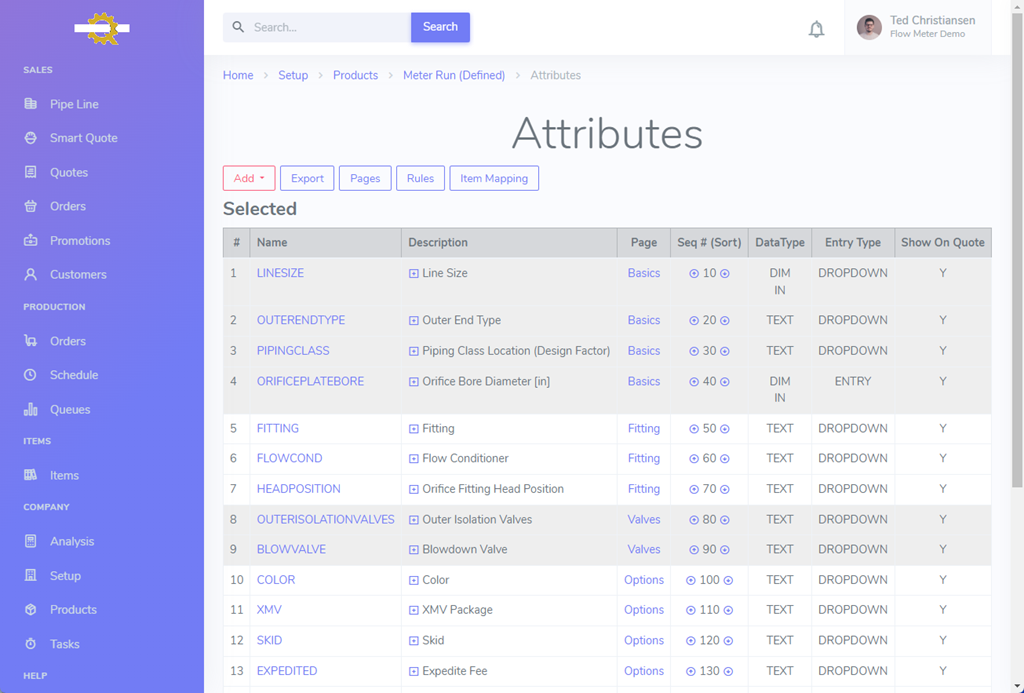

1) Attributes

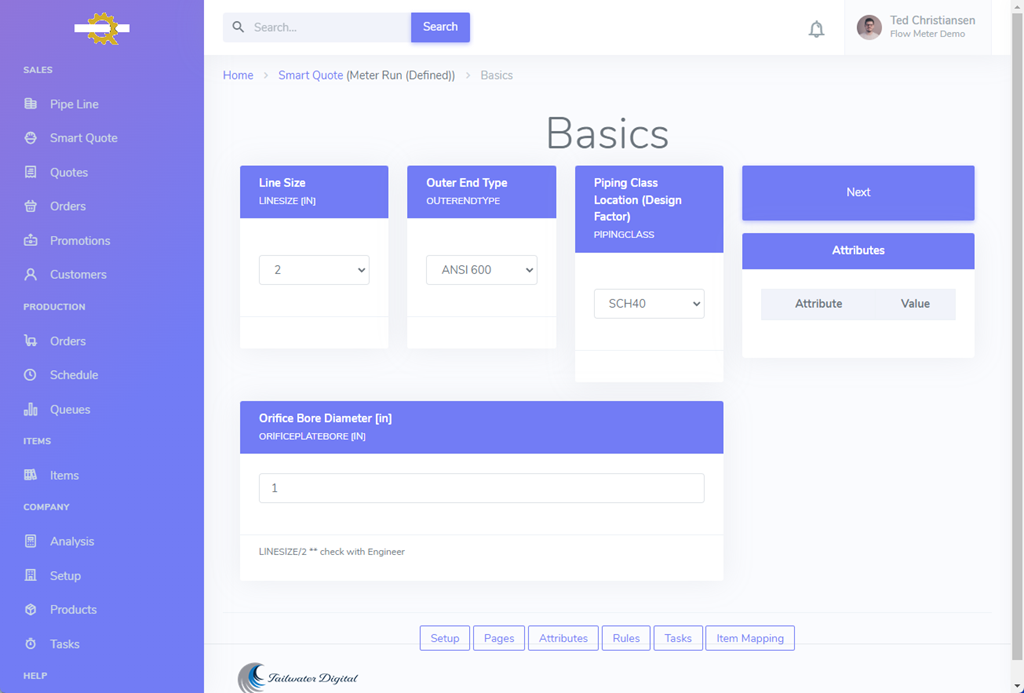

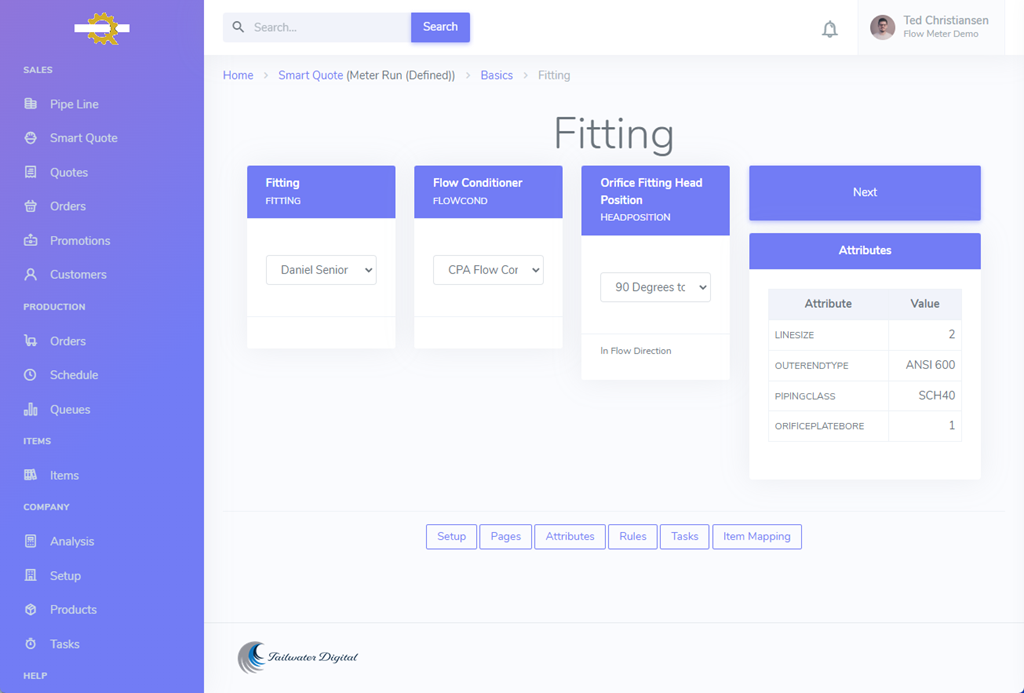

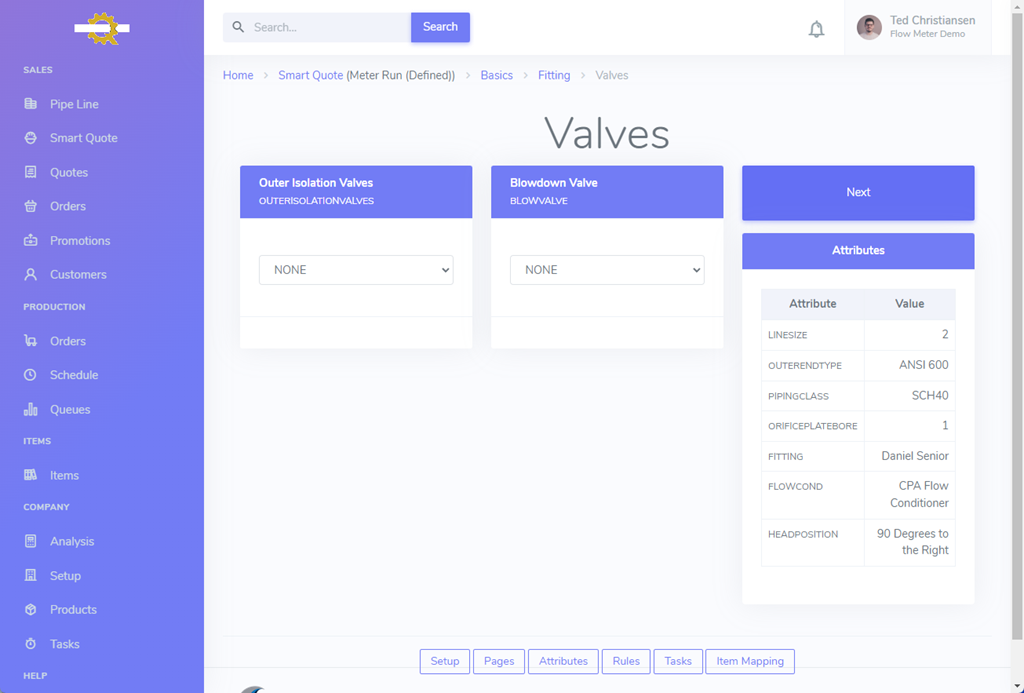

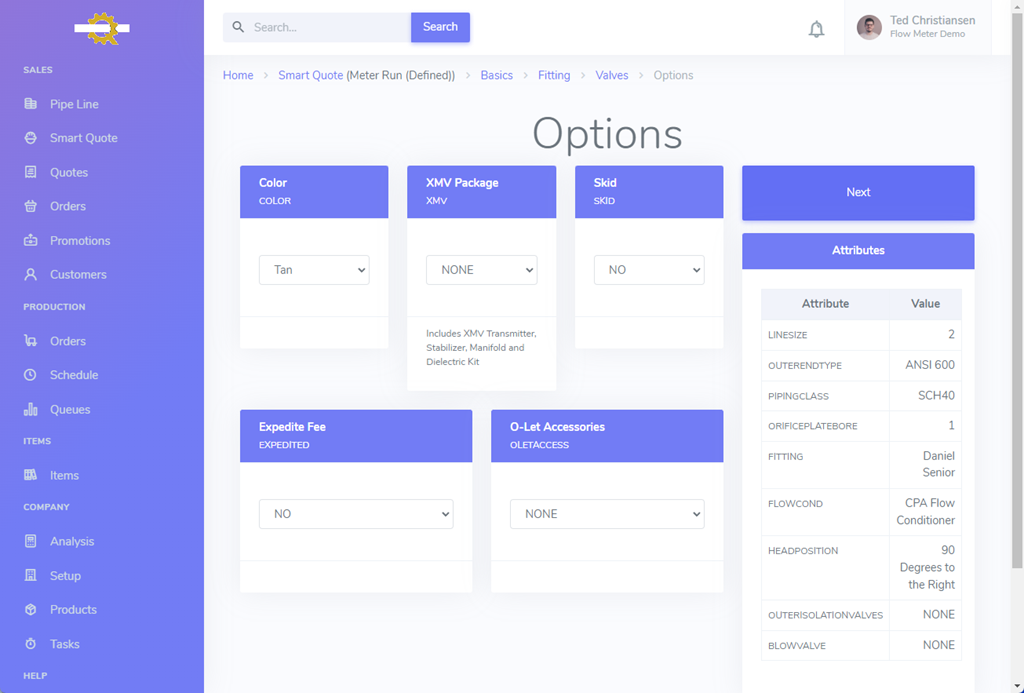

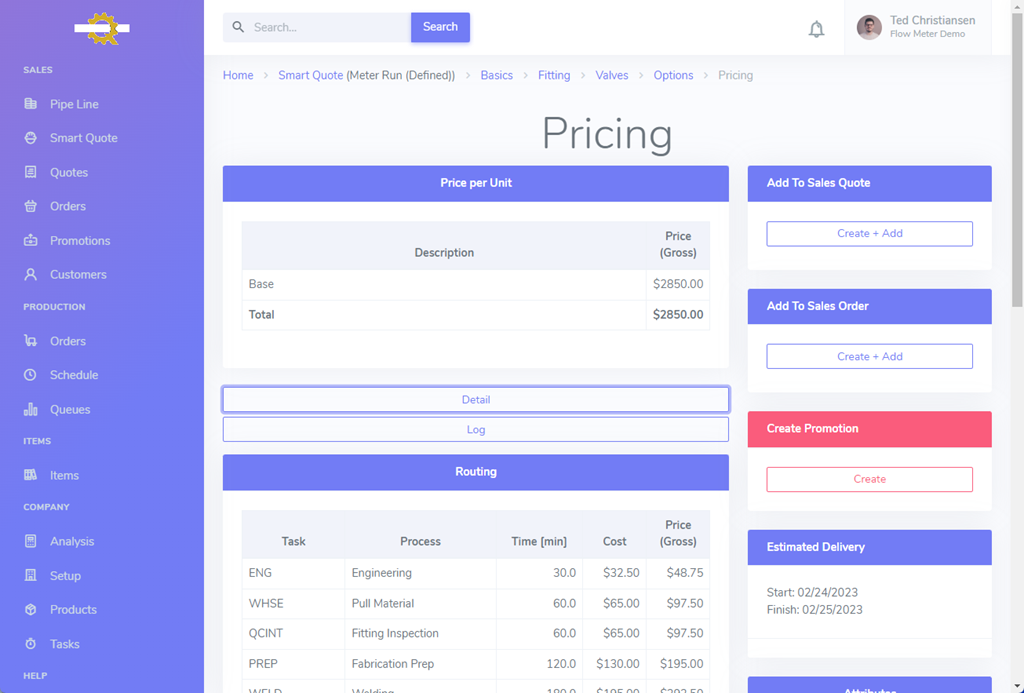

Shown below are the Attributes as setup in Velosity:

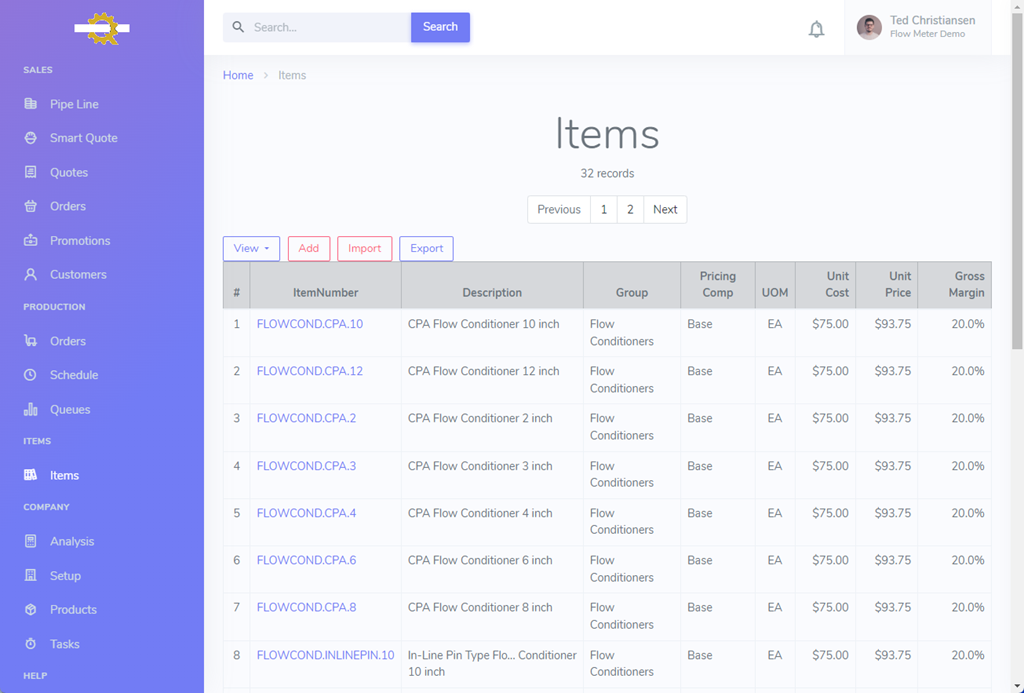

2) Items (Imported)

Shown below are Items as setup in Velosity:

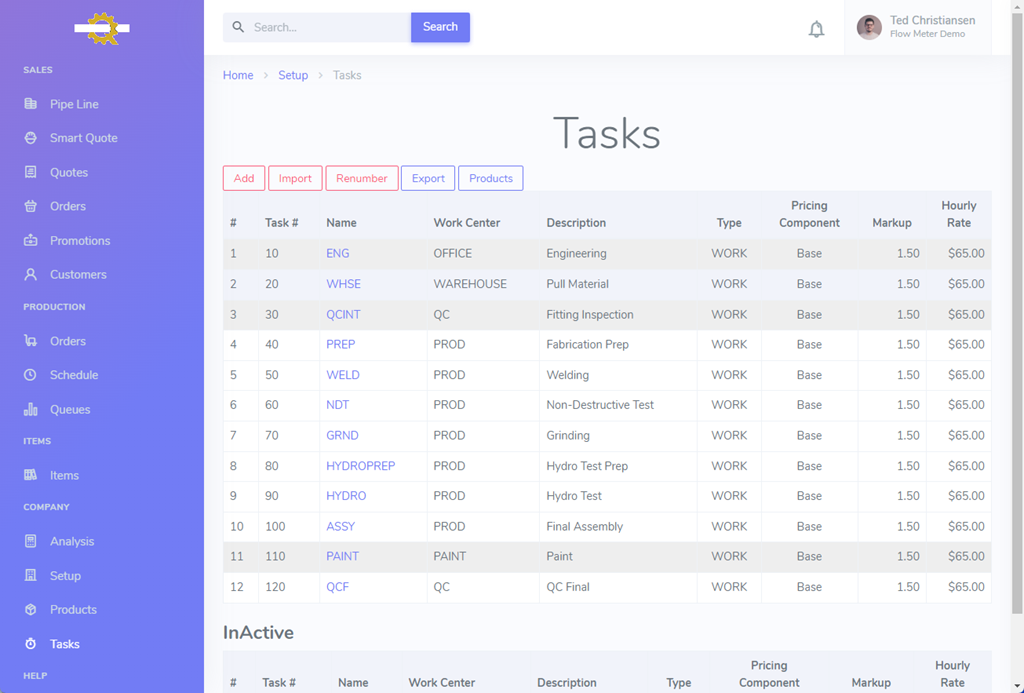

3) Tasks

Shown below are the Tasks as setup in Velosity:

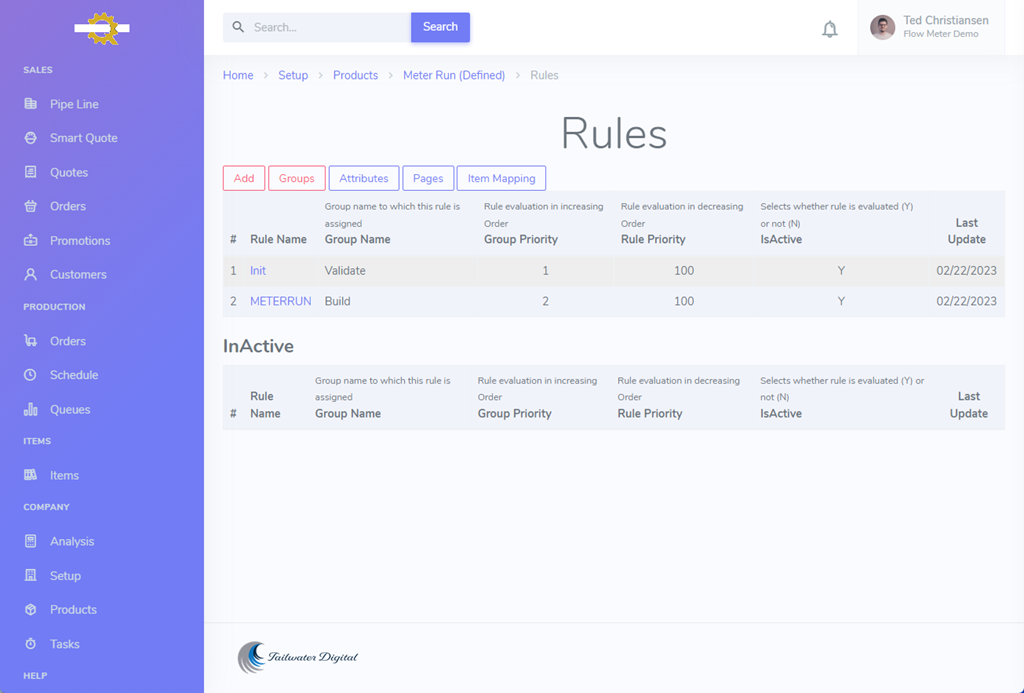

4) Rules

Shown below are Rules as setup in Velosity:

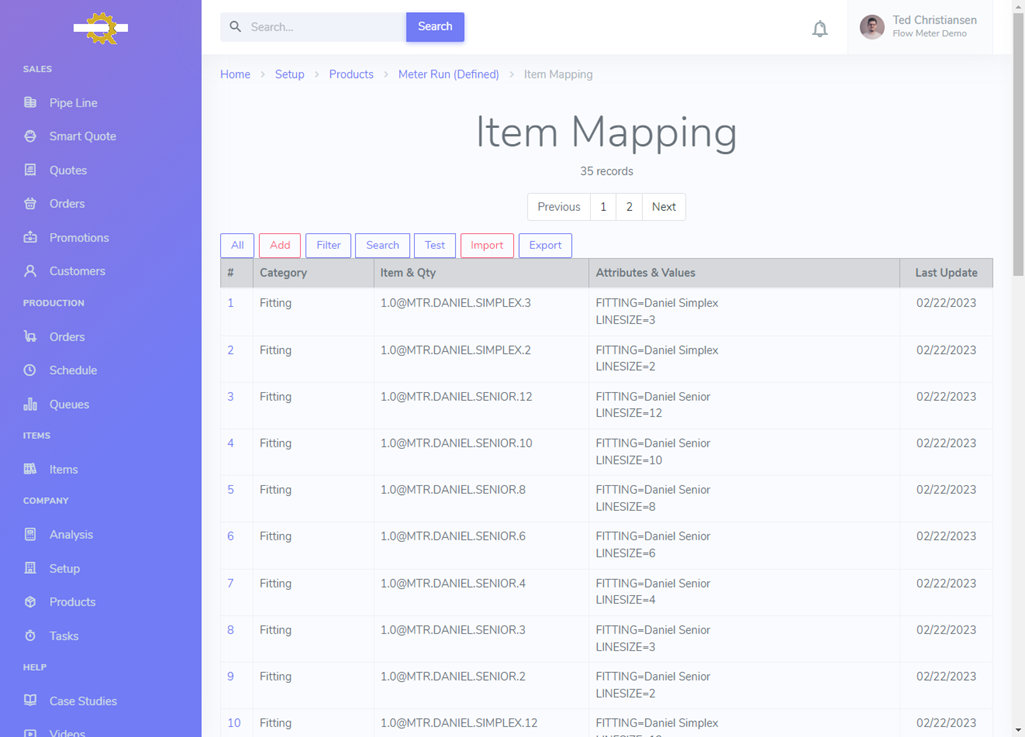

5) Item Mapping (Imported)

Shown below is the Item Mapping as setup in Velosity:

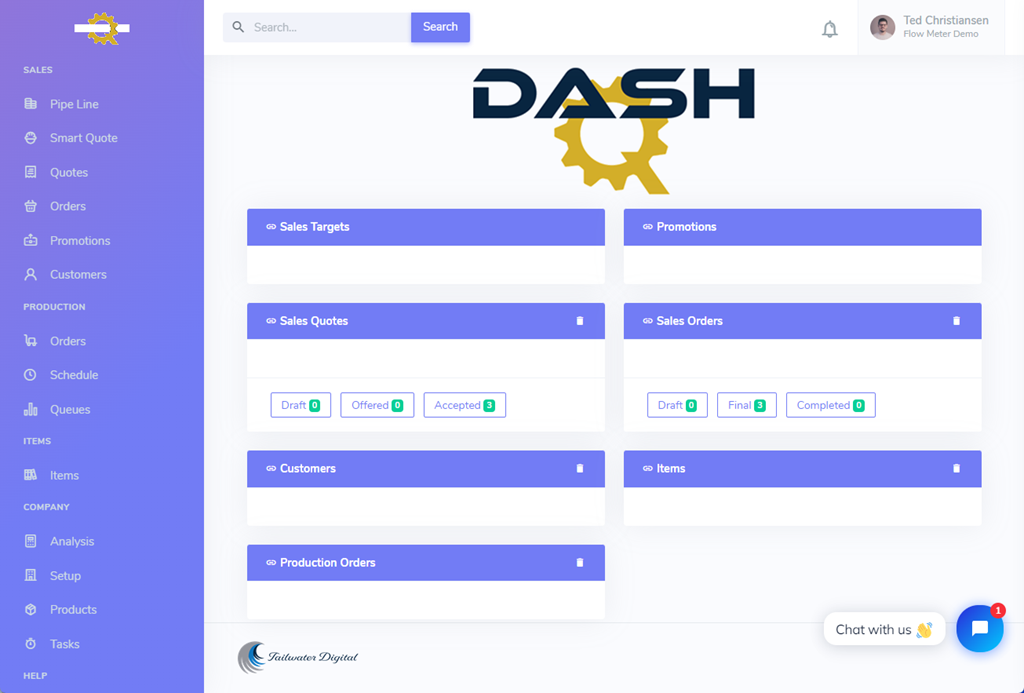

Results

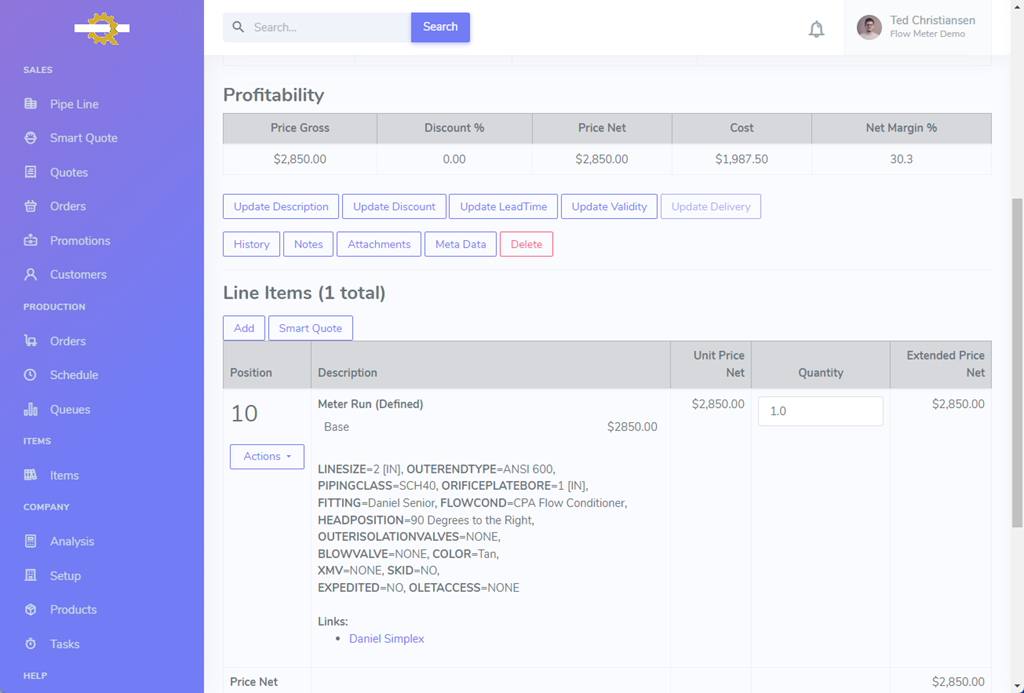

With this setup, the customer is able to generate quotes and orders in 60 seconds or less!

See it in Action