Case Study - Machine Shop

Streamline your entire process from Quoting through Production Schedule Management!

Background

The company in this case study is a machine shop where every order is different, with very little (but some) repeat business.

Because each order is different, quoting requires an understanding of both materials required and process. Materials required is typically one type of metal by grade, shape (round, billet) and dimensions. The process required is a function of the machined features in the finished part.

Because each order (line item) is unique, Velosity Smart Quote doesn't work. Instead the Velosity Line Item Editor is used to create the router and the BOM. The Tasks defined in the Company Setup are used to calculate the process cost. The BOM can use the Item Catalog (optional module) or the cost and price entered manually.

The company in this case study is a machine shop where every order is different, with very little (but some) repeat business.

Because each order is different, quoting requires an understanding of both materials required and process. Materials required is typically one type of metal by grade, shape (round, billet) and dimensions. The process required is a function of the machined features in the finished part.

Because each order (line item) is unique, Velosity Smart Quote doesn't work. Instead the Velosity Line Item Editor is used to create the router and the BOM. The Tasks defined in the Company Setup are used to calculate the process cost. The BOM can use the Item Catalog (optional module) or the cost and price entered manually.

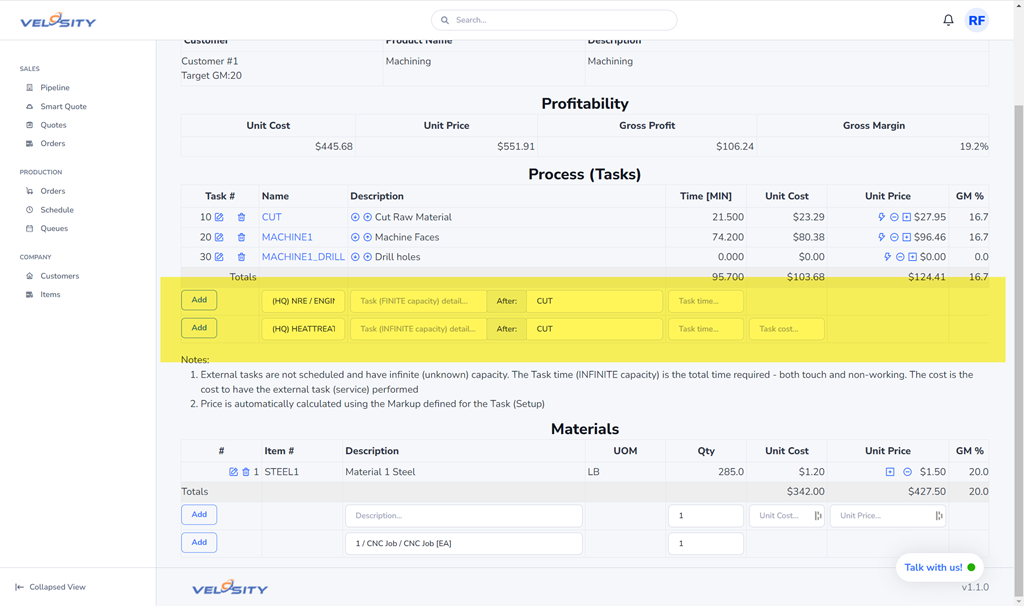

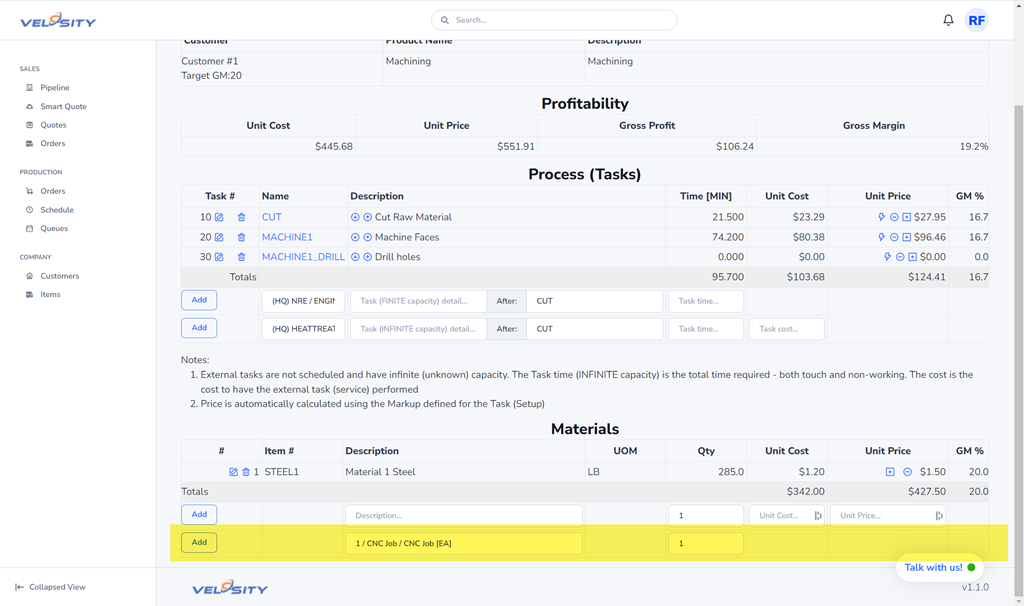

Line Item Editor - Process (Router)

The Velosity Line Item Editor allows users to create a router and BOM manually, but quickly. The Tasks defined in the Company Setup are selected from a list. Each Task has a defined hourly rate and markup (cost * markup = price). The user selects the Task and enters the time in minutes or hours. Clicking on the Add button adds the task to the router. The added Task can be edited, deleted or the sequence changed.

The total cost, price, gross profit and gross margin are updated with each change.

The Price for each Task can be increased/decresed in 10% increments (and reset) to achieve target gross margins. See it in Action (video)

Line Item Editor - BOM

The BOM is created in a similar way. The materials can be added from the Item Catalog (optional module) or entered manually. The total cost, price, gross profit and gross margin are updated with each change.

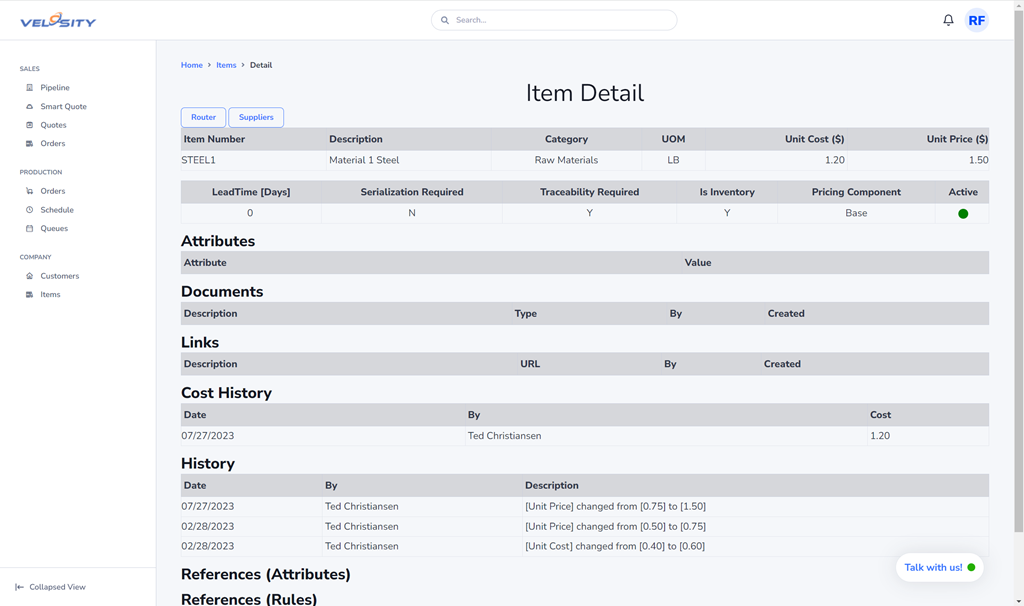

Setup / Items

The items shown in the Line Item Editor are managed in the Item Catalog. This is an optional module in Velosity that provides functionality to manage items and also inventory if desired.

Setup / Tasks

The Tasks in the Company Setup define the discrete operations available to fulfill an order. Each Task has these properties:

- Name

- Work Center

- Description

- Hourly Rate

- Markup (Cost * Markup = Price)

- Pricing Component (Optional presentation of prices by category)

- Capacity Type: FINITE (internal), INFINITE (external)

- Time: Setup, Teardown, Transfer. Used in Scheduling

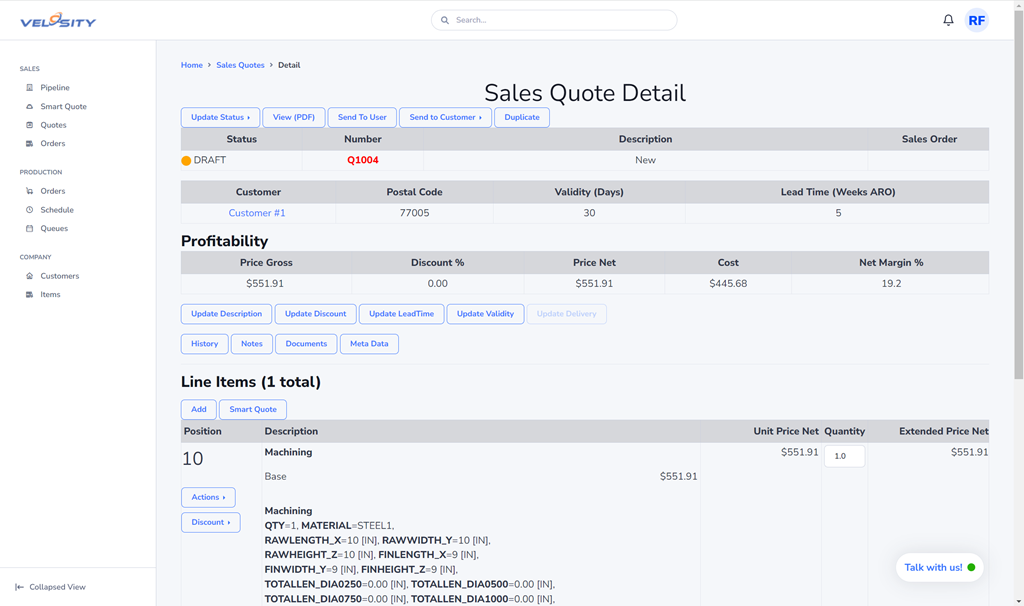

Sales Quotes

The Line Item created earlier is added to a Sales Quote in DRAFT status.

From here, various things can be done:

- Edit the Line Item

- Add another Line Item

- Save the Line Item as a template to the Customer. This allows for later re-use of the Line Item for repeat orders. Note: costs are recalculated when a template added to a new quote. Learn more

- Update the Quote discount

- Update the Quote leadtime

- Change the Status (OFFERED, ACCEPTED, LOST)

- Send to Velosity user

- Send Quote (PDF via customizable template) to the customer

- Add Notes

- Duplicate the Quote

- Delete the Quote

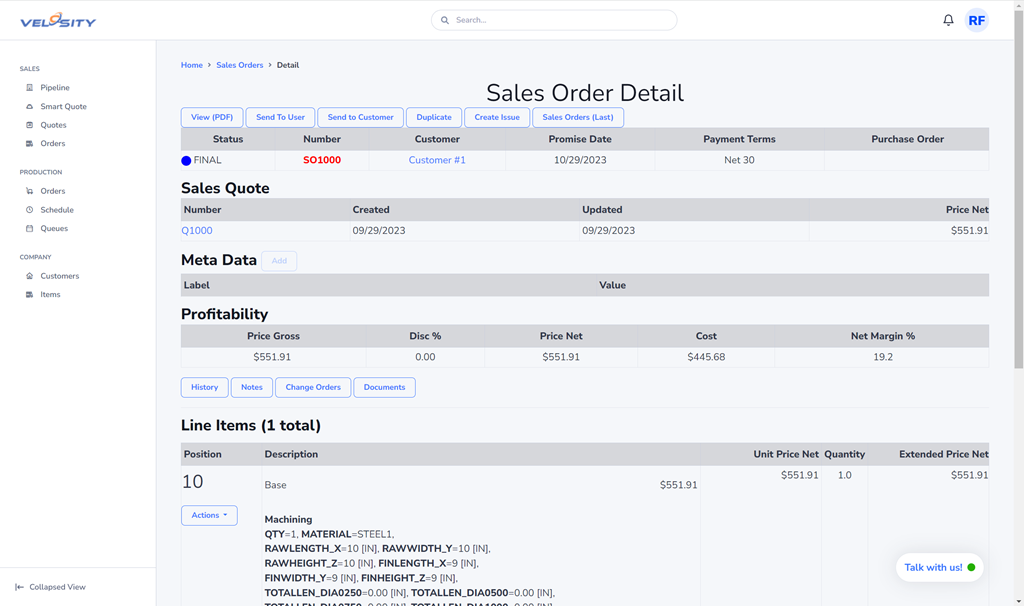

Sales Orders

A Sales Order is created when a Sales Quote status is set to either: 1) OFFEREDRESERVED, 2) ACCEPTED and is set to DRAFT status initially.

From here, various things can be done:

- Edit any Line Item

- Add new Line Items

- Update the Promise Date

- Add an external reference

- Add Notes

- Add Change Orders

- View the History

- Change the Status (FINAL, CANCELLED)

- Send to Velosity user

- Send to the customer (PDF via customizable template)

- Duplicate

- Delete

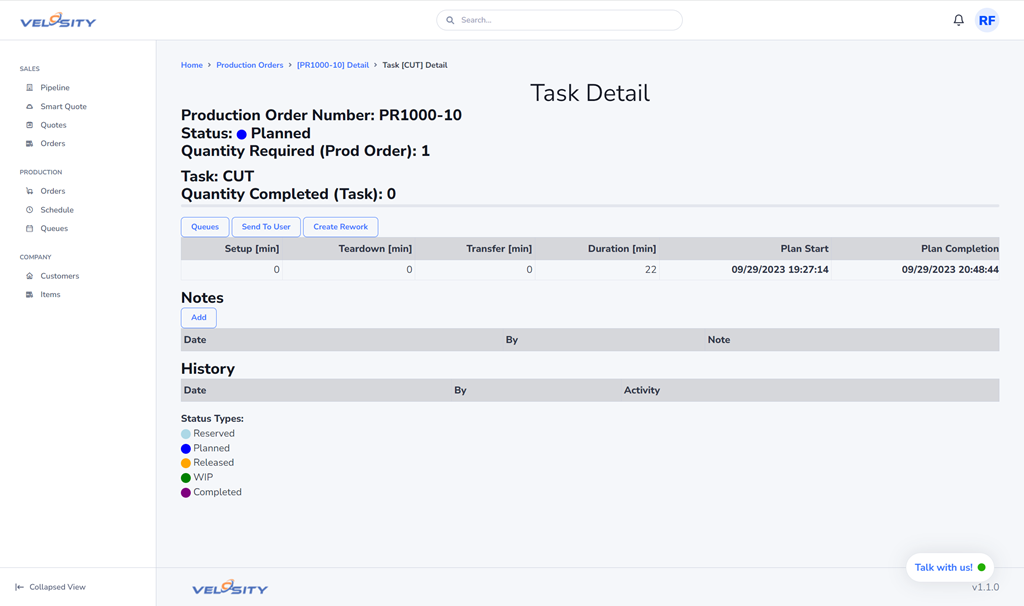

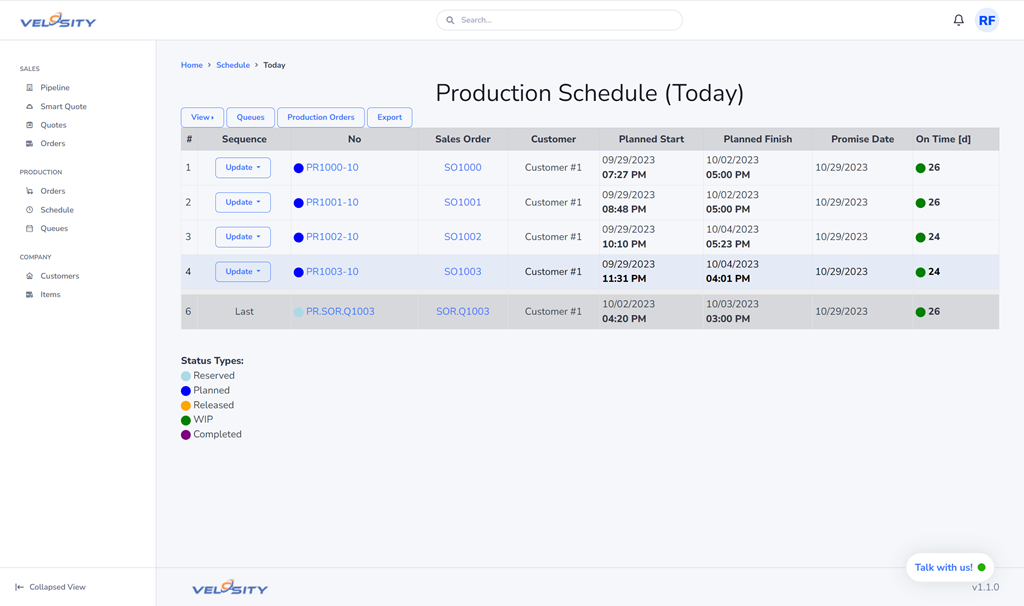

Scheduling

The production schedule can be viewed and managed within Velosity. From here, the sequence (priority) of a Production Order can be changed. Once changed, the production schedule is automatically recalculated.

The schedule can be viewed by production month - both start and finish

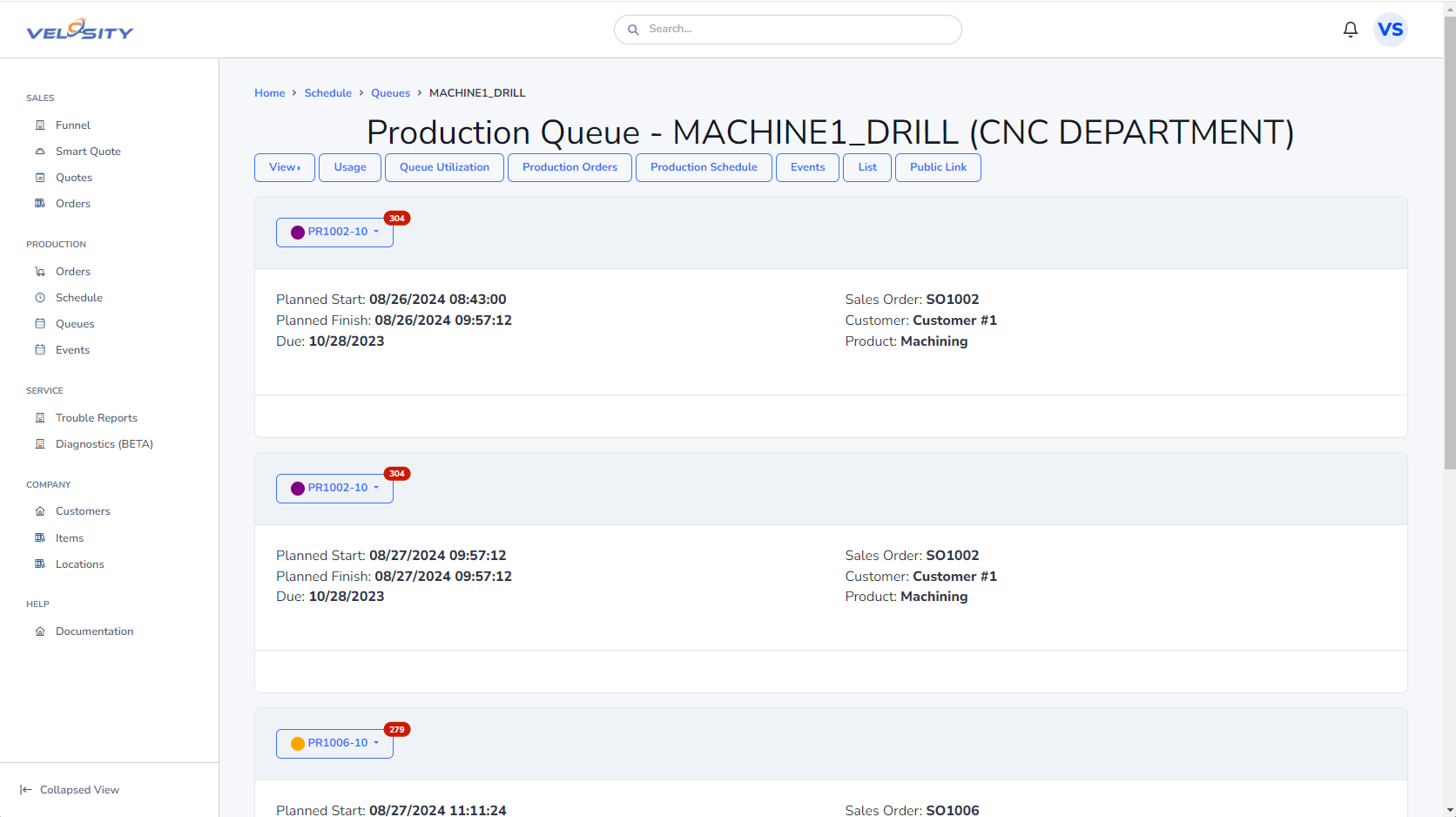

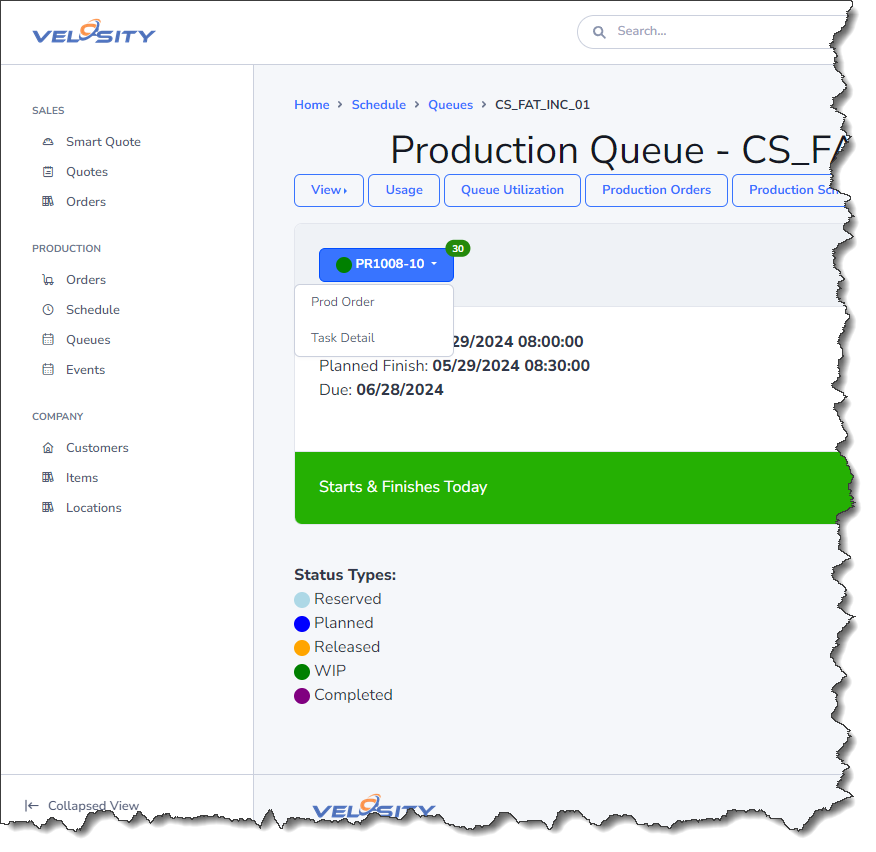

Production Queues

When the Production Scheduling feature in Velosity is used, Velosity offers users the ability to view & manage production orders by Task.

The view can be filtered to a particular WorkCenter using the dropdown menu.

Clicking on a Task shows a view of the Queue Utilization.

The date shown can be changed/selected.

Production Queue Task

Each Production Task in the company Setup is shown in a row at the top. For each Task, the Production Orders that require this Task are listed with:

- Planned Start

- Planned Finish

- Sales Order #

- Customer

- Product (Smart Quote)

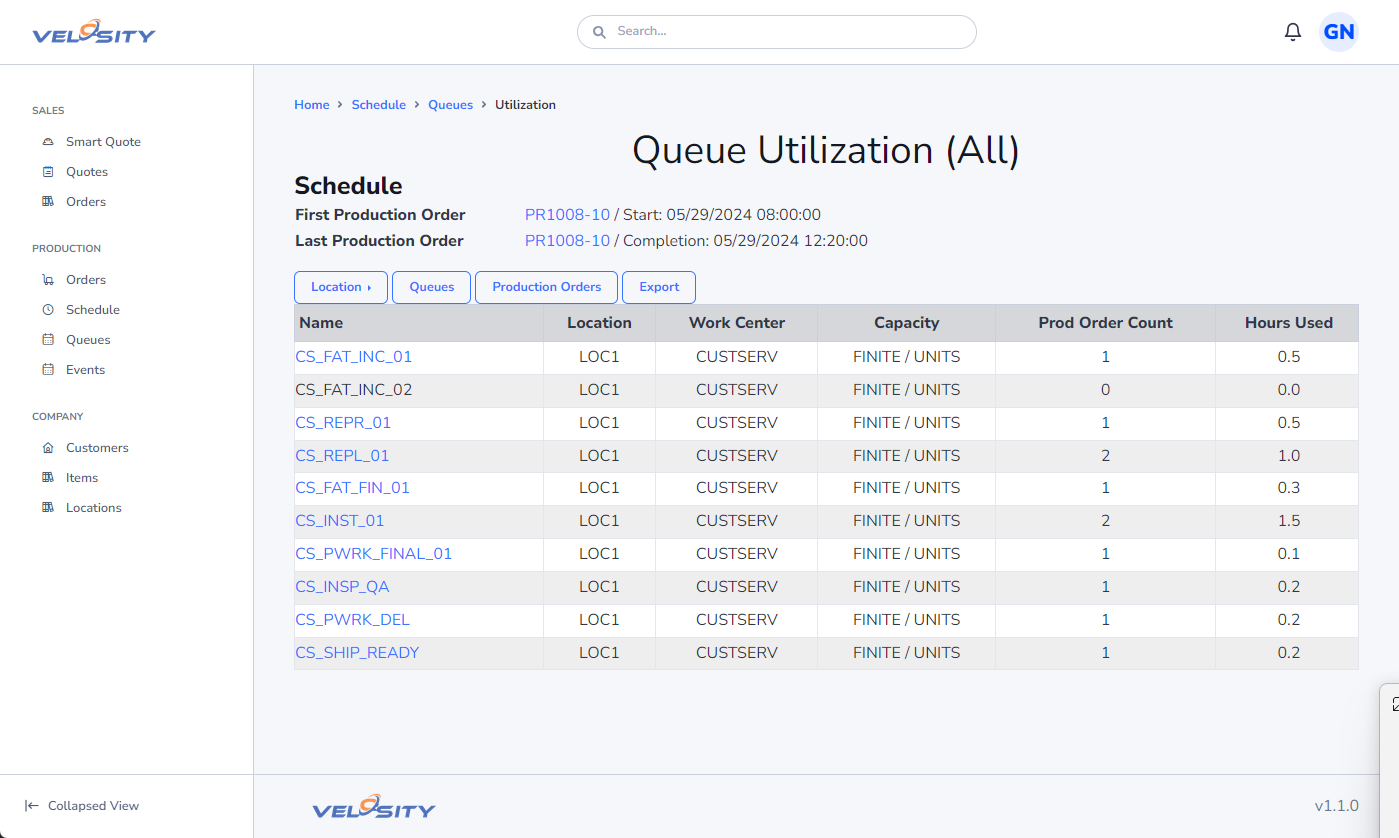

Production Queue Utilization

The Queue Utilization view shows the total hours used vs available and percent utlization.

Also listed are the Production Orders upcoming for this Task.

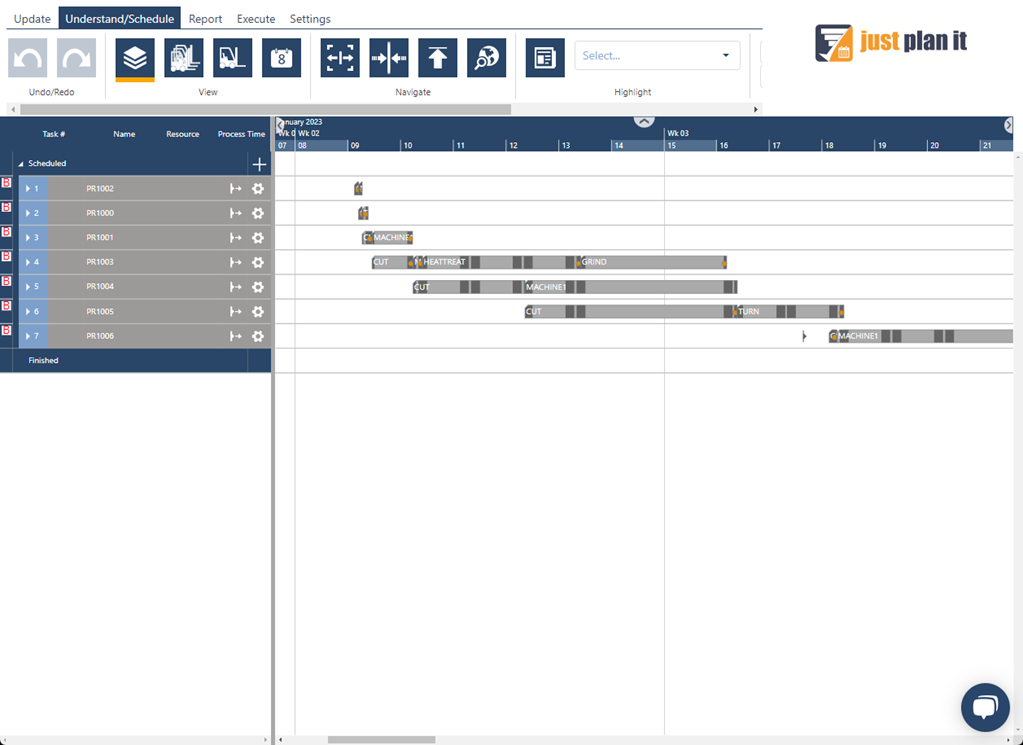

Integration (available) with just plan it

Velosity has an integration with just plan it (JPI) that can be enabled.

When enabled, Velosity will send new and changed production orders to JPI - which will update the schedule automatically. This schedule is kept in sync with Velosity.

Learn more (video)

See It in Action

Results

Velosity transformed the quote and order management processes for this company compared to Excel being used previously. It also gained the ability to quickly view and use historical quotes and orders. The Company gained automatic production scheduling that previously had been very time consuming and error prone to manage using Excel.