Case Study - Customer Service (RMA) - Quoting & Scheduling

Streamline your entire RMA process from Quoting through work order execution and scheduling!

Background

The company in this case study provides service on its products to customers for both warranty and upgrades. Turnaround time was not to desired level and the company was seeking ways to eliminate time waste.

Problem

Many companies - including this one - calculate cost and pricing for quotes and sales orders in Excel. The time (cost) of each repair was estimated manually. Each replacement part required was added manually after looking up the cost in the ERP. This company had not even attempted to create and manage a schedule in Excel. This means that it could never provide an estimated completion date to the customer - leading to poor customer experience

One solution could be to use the ERP already in place for manufacturing. The problem with this approach is that each combination of required repair operations would require the creation of a dummy part number and router - simply to determine the cost! Doing so would give the company a schedule and thus estimate completion dates. However, it would be much slower than Excel and might require more staffing just to get this benefit.

Solution

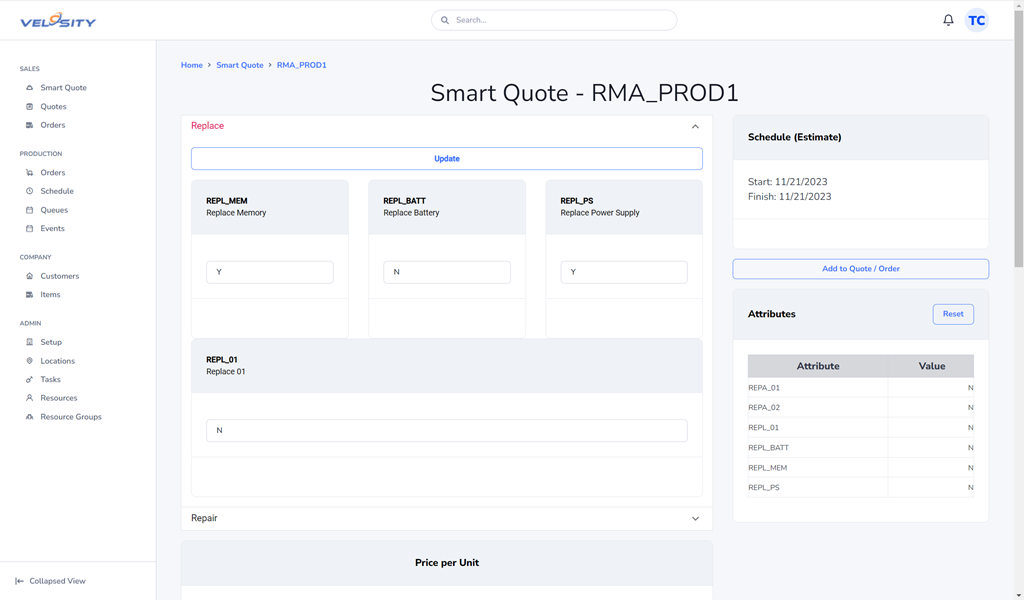

Velosity was able to solve this problem uniquely. Because Velosity automatically creates the router and BOM in seconds - it eliminates the manual work that an ERP approach would require. Velosity generates the router and BOM dynamically based on the product features (attributes) selected. The router even includes high level work detail!

- Attributes (Product Specific)

- Items

- Tasks (Process Steps)

- Rules (Product Specific)

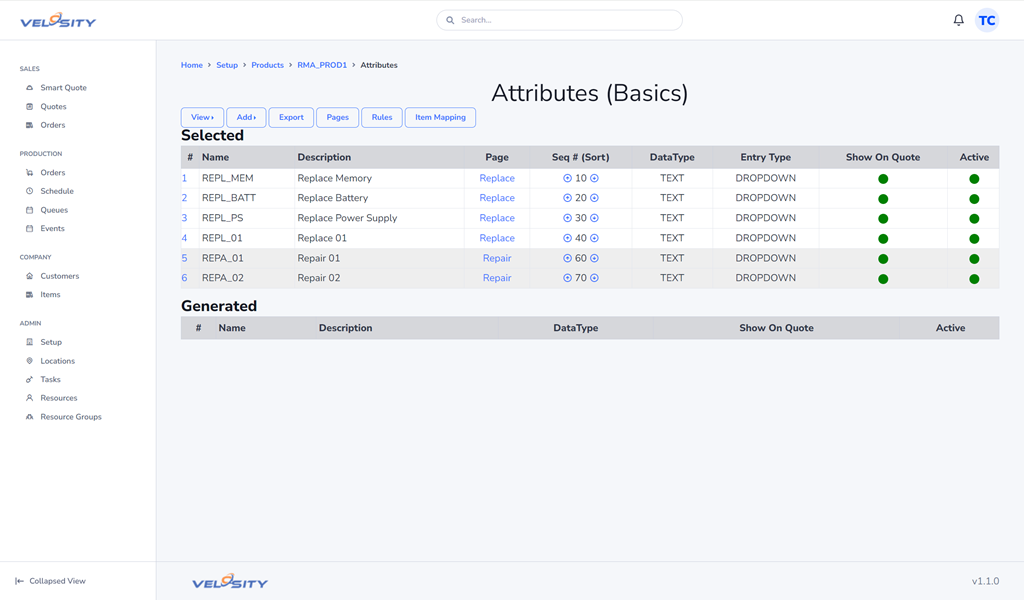

1) Attributes (One Product)

Shown below are the Attributes as setup in Velosity

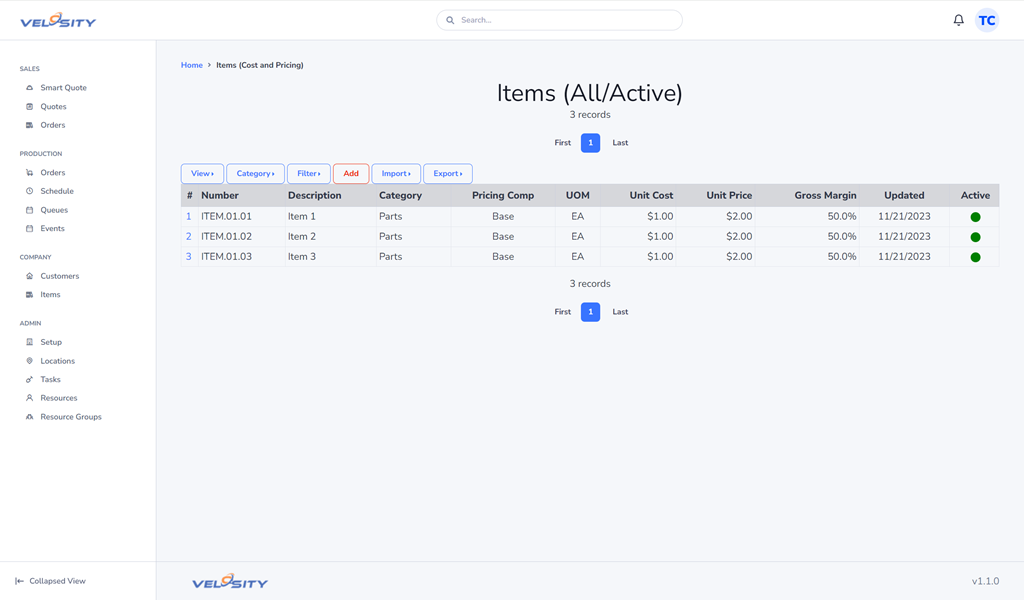

2) Items

Shown below are Items as setup (imported via CSV) in Velosity

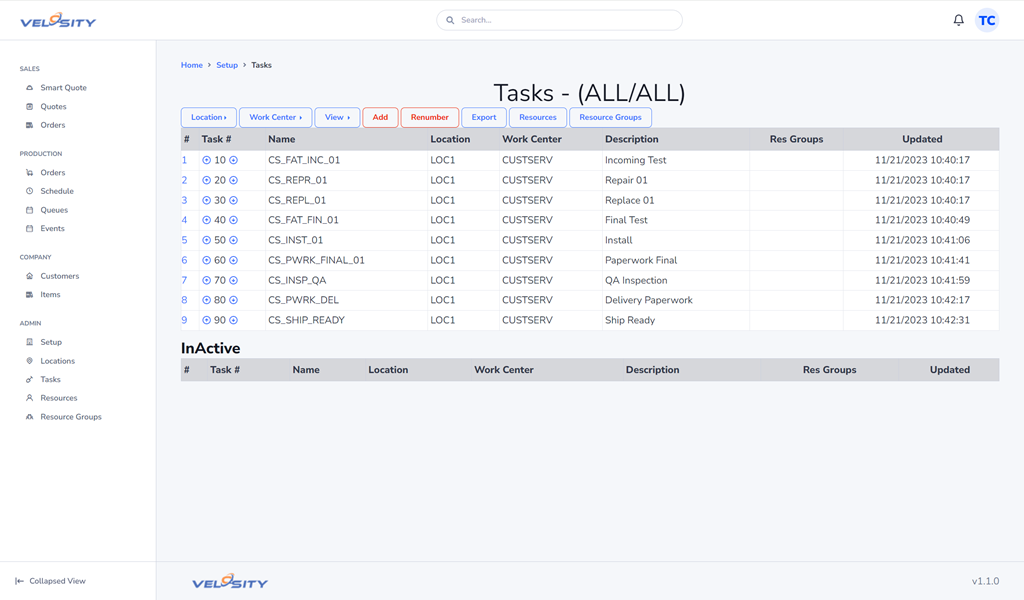

3) Tasks

The process steps (tasks) for this company are:

- CS_DIAG (Diagnose)

- CS_REPR (Repair)

- CS_REPL (Replace)

- CS_PRWK (Paperwork)

Shown below are the Tasks as setup in Velosity

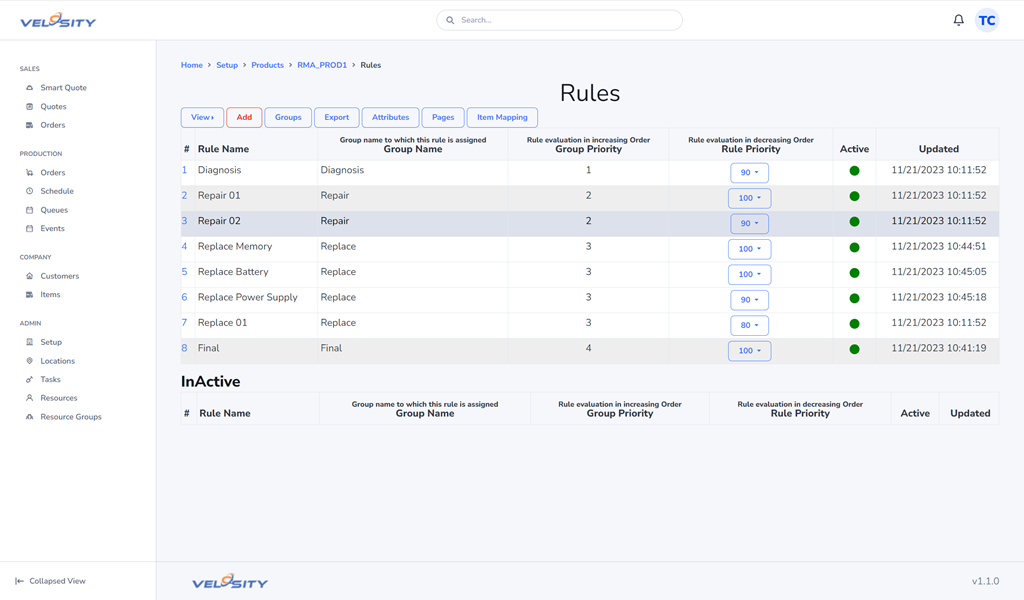

4) Rules

Shown below are Rules as setup in Velosity

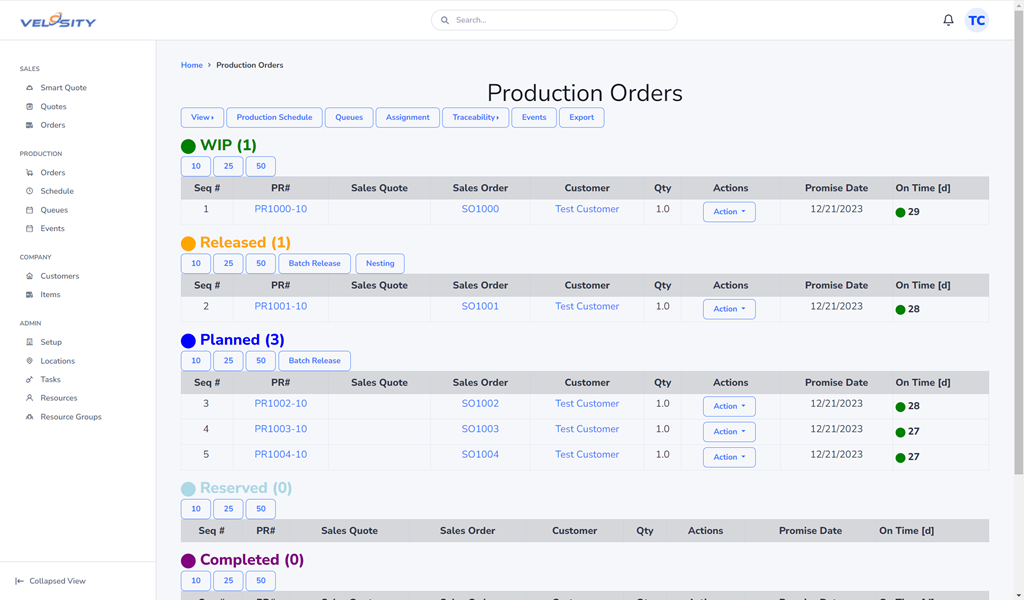

Production Orders

When Sales Orders are update to Status=FINAL, Velosity creates a Production Order for each line item on the Sales Order. These Production Orders define what is to done to complete the RMA for the customer.

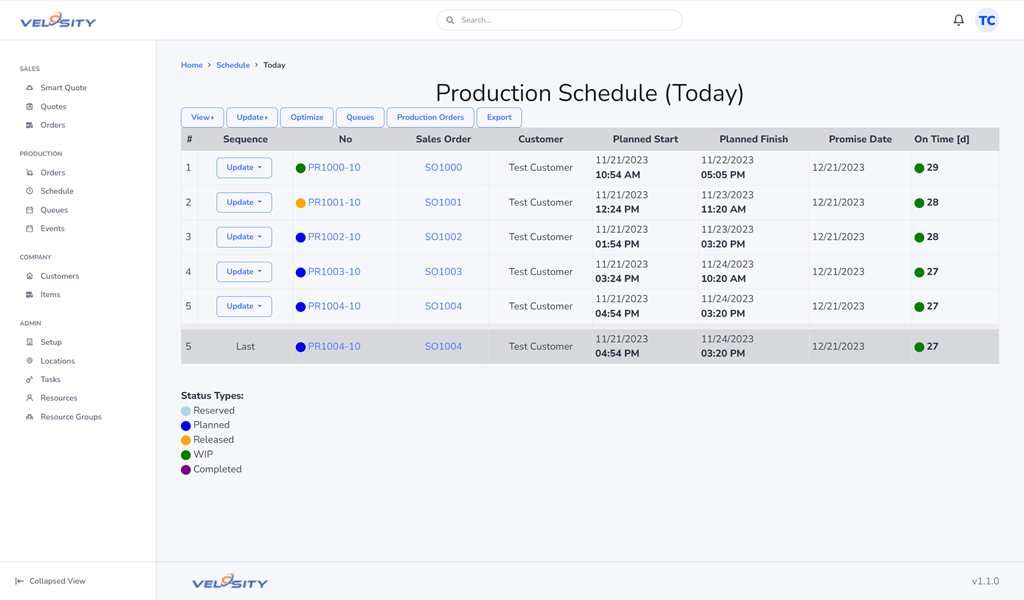

Schedule

Velosity calculates a Production Schedule from the Production Orders, taking into account working hours and holidays. The priority of a Production Order can be changed with a button click - triggering a recalculation of the production schedule.

Conclusion

Velosity enabled this company to dramatically speed up its quoting and sales order processes for RMA. The schedule Velosity provided enabled the company to give customers a dependable completion estimate - improving customer satisfaction.