Part 2 — Introducing DashQ : A quote+delivery solution for build-to-order businesses

- Date: 10/16/2022

- Audience: CEOs, Sales Managers

- Topics Covered:

- ERP

- Configured Products

- Quoting

- Smart Quote

- Router

- Bill of Materials

- Build-to-Order

In Part 1 we introduced Velosity — a hybrid of CPQ and ERP designed for small to medium sized businesses delivering products or services that are “build-to-order” or ala-carte. As explained in Part 1, this makes determination of the Cost of Sales or Cost of Goods Sold at the quoting phase so time consuming that an approximation is used instead of precisely known costs.

In this article we will compare Quoting in Velosity vs Excel and Velosity vs ERP.

Configured Product Quoting in Excel

Many small companies manage their business processes using Excel plus an accounting solution such as QuickBooks. Excel is used for quoting, lists of sales orders, production orders. When quoting a configured manufactured product, a time estimate of the process steps required is created using historical data and experience based “best guess.” An estimate of the materials required is created — which is typically easier to know with certainty. One example is shown below.

Excel — Example Estimate of Time and Cost per Work Step

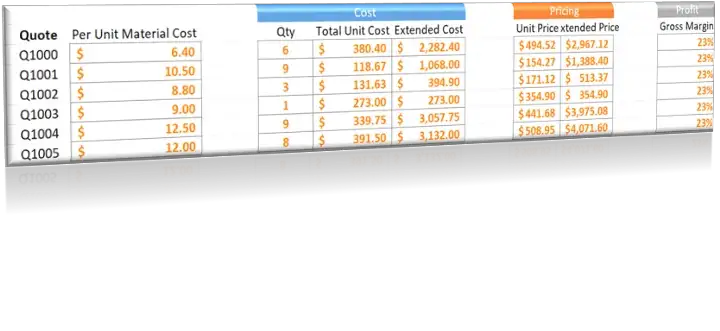

The materials required must also be estimated. Summing the material and process cost results in total cost per unit. Applied a markup determines price per unit and gross profit margin

Excel — Example Material Cost, Pricing, Profit

The Excel approach can function reasonably well, but will eventually expose its limitations. While extremely flexible, an Excel solution has at least these disadvantages:

- Room for error — formulas, incorrect values

- Challenging to maintain single source of truth because of data duplication

- Encourages unwanted proliferation of versions of this data by various disciplines in the business: production, accounting, etc. Significant time is wasted keeping these versions of documents synchronized manually

Configured Product Quoting in ERP

Quoting a build-to-order product in an ERP software requires the following steps:- Create top level (assembly) part number

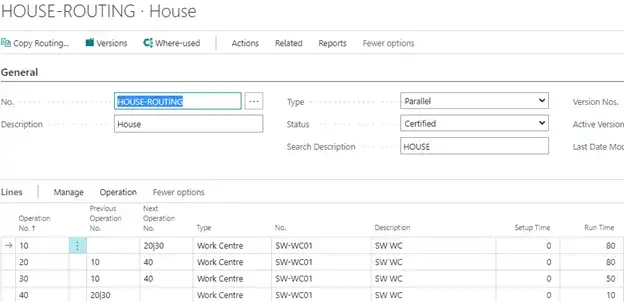

- Create a manufacturing router associated with this part number. The time required for each step must be estimated and updated. ERP often supports a copy/paste or duplicate/edit feature, which makes this process less cumbersome

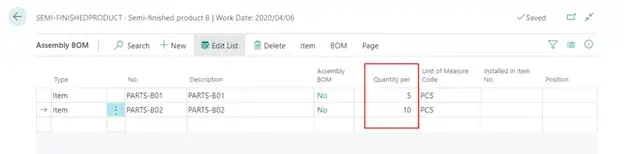

- Create a bill of materials associated with this part number. This means searching for each sub-assembly or item, adding each — one by one

ERP — Create BOM

ERP — Create Routing

Configured Product Quoting in Velosity

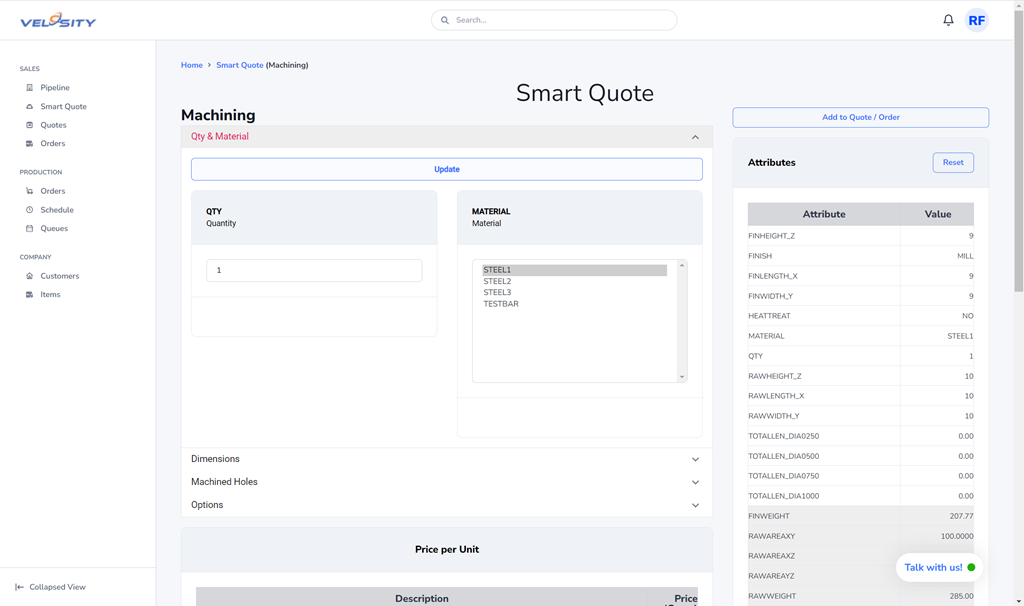

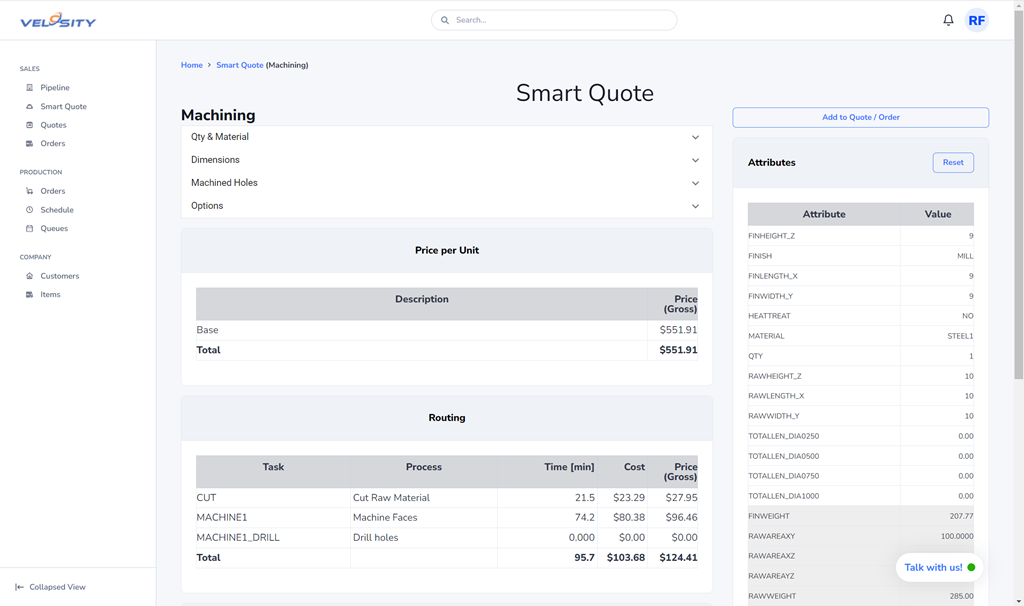

Velosity eliminates this repetitive work in ERP or Excel, beginning with Quoting. Using the Configurator, a a price can be determined quickly with an interface that is very similar to the “build your own” feature on car company websites. The Attributes presented and Pages are unique to each company using Velosity — defined in the Setup (more details in a future article).

When completed, the Configuration view shows the pricing, and detail of production router and BOM. This configuration can optionally be added to an existing quote (DRAFT) or a new quote.

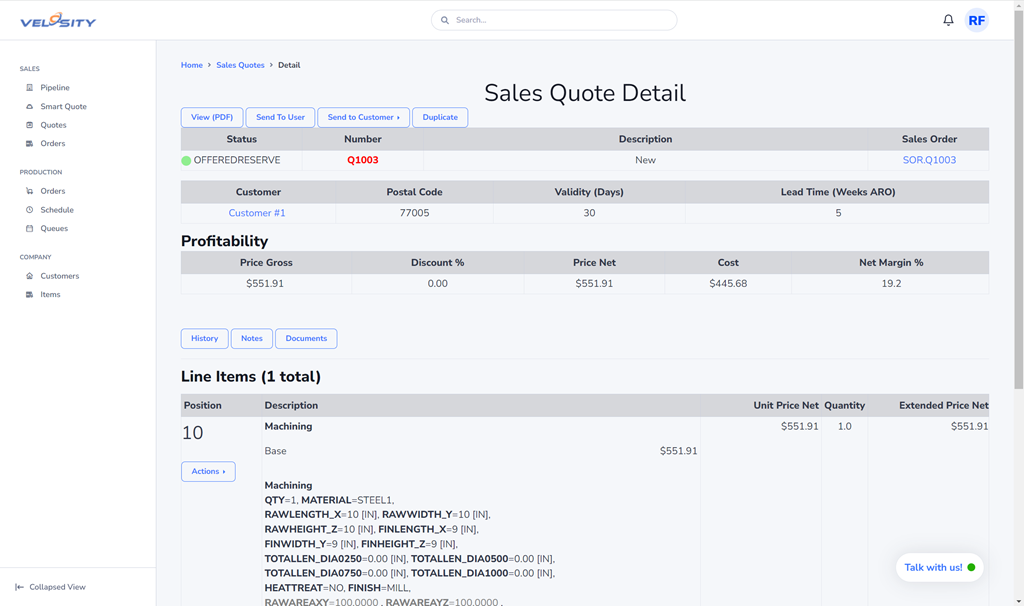

The configuration process is repeated for the desired number of line items on the quote.

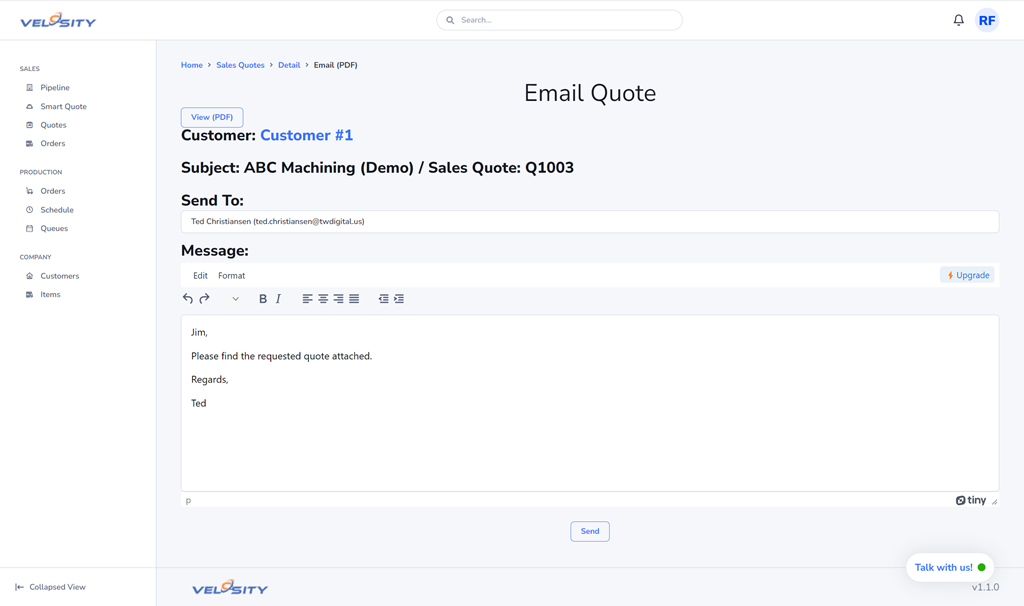

While the quote is in DRAFT status, line items can be added, removed, or the quantities updated. Once ready to submit to the customer, the Status is change to OFFERED. The quote can be emailed directly to the customer from within Velosity (as PDF), or the PDF can be downloaded and emailed separately.

Velosity simplifies the quoting process for Sales dramatically and at the same time improves the precision of the cost — improving margins. Having a production router and Bill of Materials at the quoting stage eliminates “churn” in downstream processes of Sales Order acceptance, Production Order creation and Scheduling.

In the next article we will take a closer look at Sales Orders.

Visit us at: http://www.velosity.app or https://my.velosity.app

Follow us on LinkedIn: https://www.linkedin.com/company/tailwaterdigital