Part 1 — Introducing DashQ : A quote+delivery solution for build-to-order businesses

- Date: 9/30/2022

- Audience: CEOs, Sales Managers

- Topics Covered:

- ERP

- Configured Products

- Quoting

- Strike Rate

- Router

- Bill ofM Materials

- Build-to-Order

ERP software began in the 1960’s as Material Resource Planning, the first known instance where J.I. Case — a manufacturer of tractor and construction machinery — worked with IBM to develop the first MRP system. Adoption grew in the 1970s, but remained exclusive to large companies with the capital and scope of material planning problem. In the 1990s MRP became known as ERP with the addition of busines functions such as sales and accounting.

Certain features of the design ERP have remained largely unchanged. Knowing the cost and price of a line item at the quoting stage requires the following:

- A top level (assembly) part number. This part number serves as the reference for everything related to it.

- Bill of Materials. A list of materials required to make the product or perform the service

- A production routing (router). The sequence of steps required to make the product or perform the service. Each step has a A) Resource, B) work center, C) Time Required to complete the step

This approach has proven to be robust and manageable at scale for companies making non-configured products, aka Stock Keeping Units. Companies in this kind of business do not allow customers to select which options they want. Instead, these companies define the feature set for each product they want to offer. By extension the process for manufacturing is defined as well.

Configured Products

What about the segment of industry where the customer can choose the options, such as: car companies, machine shops, additive manufacturing services, sign makers, rubber manufacturers, aircraft repair. Each of these examples has numerous product categories, each of which have a unique set of features (attributes + # choices/levels). The numerical calculation of combinations gets to be a large number quickly.For companies in the build-to-order business, why does this matter? Recall the three requirements of ERP software for each line item. The quote win/lose ratio (strike rate) is typically 10–30%. For every ten quotes prepared and submitted, only 1–3 become sales orders. Satisfying the ERP requirements means that each unique combination of attributes (features) requires the creation of a unique assembly part number, BOM, router! Eventually, thousands or tens of thousands will be created over time. Seven out of ten are “wasted effort” because the sales orders were not won.

Is there a better way? Fortunately, yes.

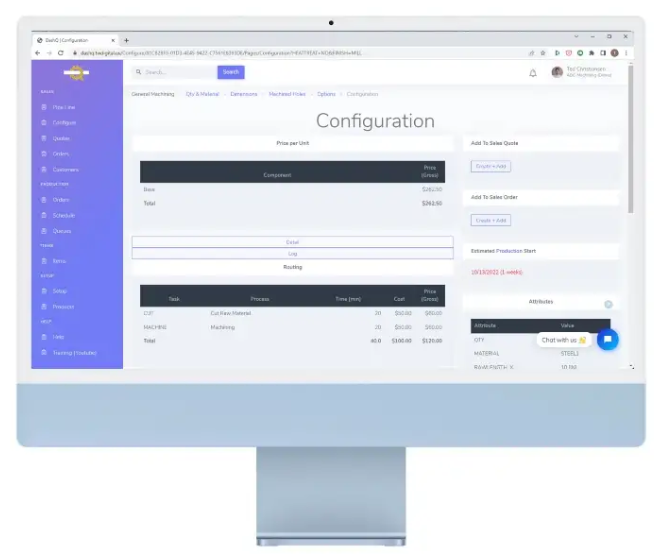

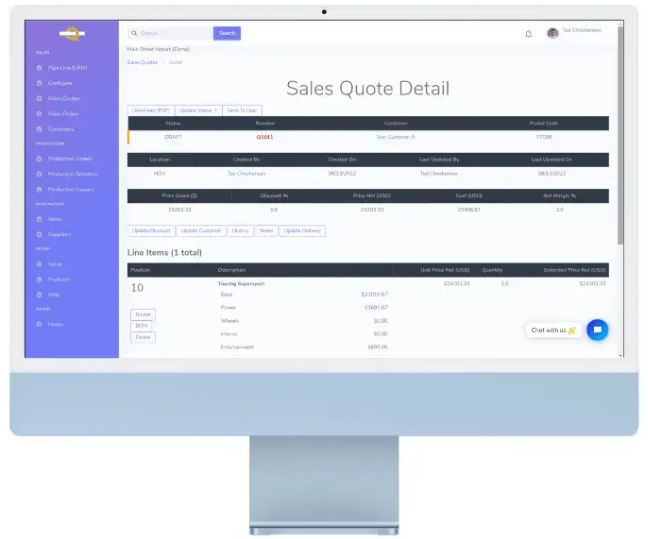

Velosity (https://my.velosity.app) entirely eliminates the requirement to create the assembly number/router/BOM. Through a unique approach, Velosity creates the router and BOM dynamically based on the product attributes selected. The definition that achieves this is improved over time — becoming more intelligent. A user can price a product in single digit minutes, compared to hour(s) for many such companies. An entire quote with multiple line items can be created in ten minutes or less.

With a complete and accurate definition of routing and BOM during quoting, downstream activities such as Sales Orders, Production Orders are available with ZERO editing.

The next installment will look at sales orders and production orders.

Visit us at: http://www.velosity.app or https://my.velosity.app

Follow us on LinkedIn: https://www.linkedin.com/company/tailwaterdigital